- Portada

- Sobre

- Productos

- Proyecto

- Fábrica

- Noticias

- Servicios

- Calidad

- Contáctenos.

Español

Español

English

English Español

Español Русский

РусскийEstamos comprometidos a proporcionar a los clientes de todo el mundo un servicio de ventanilla única de productos de tubería de acero.

El revestimiento de pozo API SPEC 5CT se utiliza para fijar la pared del pozo o el fondo del pozo, que tiene diámetros más amplios. API SPEC 5CT se puede dividir en carcasa de conductor, carcasa técnica y carcasa de aceite.

|

Carcasa API 5CT |

Rango 1 |

Rango 2 |

Rango 3 |

|

4,88 ~ 7,62 |

7,62 ~ 10,36 |

10,36 ~ 14,63 |

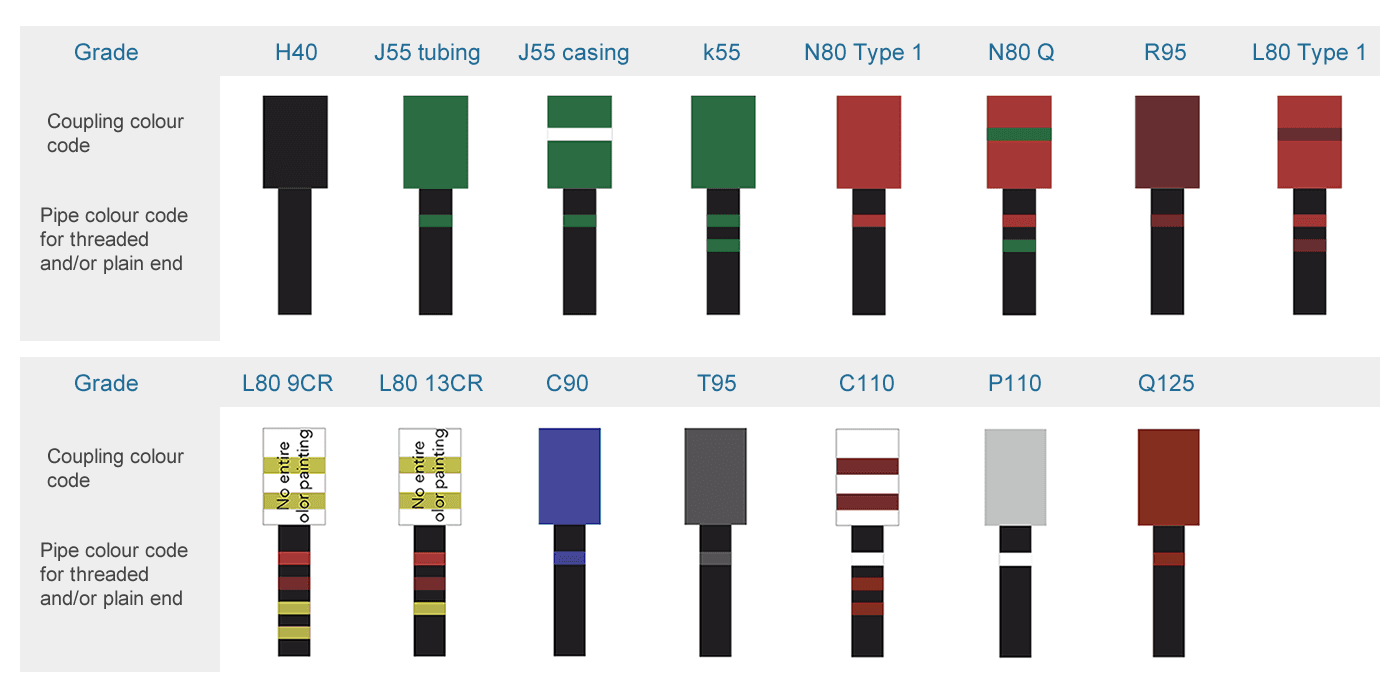

Casing&tubing y sus colores:

|

Etiquetas |

OD(mm) |

WT(mm) |

J55/K55 |

N80 |

L80 |

C90/T95 |

P110 |

Q125 |

|

|

4 1/2 |

9.5 |

114.3 |

5.21 |

PS |

- |

- |

- |

- |

- |

|

10.5 |

114.3 |

5.69 |

PSB |

- |

- |

- |

- |

- |

|

|

11.6 |

114.3 |

6.36 |

PSLB |

PLB |

PLB |

PLB |

PLB |

- |

|

|

13.5 |

114.3 |

7.37 |

- |

PLB |

PLB |

PLB |

PLB |

- |

|

|

15.1 |

114.3 |

8.56 |

- |

- |

- |

- |

PLB |

PLB |

|

|

5 |

11.5 |

127 |

5.59 |

PS |

- |

- |

- |

- |

- |

|

13 |

6.43 |

PSLB |

- |

- |

- |

- |

- |

||

|

15 |

7.52 |

PSLBE |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

18 |

9.19 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

21.4 |

11.10 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

23.2 |

12.14 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

24.1 |

12.7 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

5 1/2 |

14 |

139.7 |

6.20 |

PS |

- |

- |

- |

- |

- |

|

15.5 |

6.98 |

PSLBE |

- |

- |

- |

- |

- |

||

|

17 |

7.72 |

PSLBE |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

20 |

9.17 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

23 |

10.54 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

26.8 |

12.7 |

- |

- |

- |

P |

- |

- |

||

|

29.7 |

14.27 |

- |

- |

- |

P |

- |

- |

||

|

32.6 |

15.88 |

- |

- |

- |

P |

- |

- |

||

|

35.3 |

17.45 |

- |

- |

- |

P |

- |

- |

||

|

38 |

19.05 |

- |

- |

- |

P |

- |

- |

||

|

40.5 |

20.62 |

- |

- |

- |

P |

- |

- |

||

|

43.1 |

64.14 |

- |

- |

- |

P |

- |

- |

||

|

6 5/8 |

20 |

168.28 |

7.32 |

PSLB |

|

|

|

|

|

|

24 |

8.94 |

PSLBE |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

28 |

10.59 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

32 |

12.06 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

7 |

20 |

177.8 |

6.91 |

PS |

|

|

|

|

|

|

23 |

8.05 |

PSLBE |

PLBE |

PLBE |

PLBE |

- |

- |

||

|

26 |

9.19 |

PSLBE |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

29 |

10.6 |

|

PLBE |

PLBE |

PLBE |

PLBE |

|

||

|

32 |

11.51 |

|

PLBE |

PLBE |

PLBE |

PLBE |

|

||

|

35 |

12.65 |

|

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

38 |

13.72 |

|

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

7 5/8 |

26.4 |

193.67 |

8.33 |

PSLBE |

PLBE |

PLBE |

PLBE |

- |

- |

|

29.7 |

9.52 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

33.7 |

10.92 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

39 |

12.7 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

42.8 |

14.27 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

45.3 |

15.11 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

47.1 |

15.88 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

8 5/8 |

24 |

219.08 |

6.71 |

PS |

- |

- |

- |

- |

- |

|

28 |

7.72 |

- |

- |

- |

- |

- |

- |

||

|

32 |

8.94 |

PSLBE |

- |

- |

- |

- |

- |

||

|

36 |

10.16 |

PSLBE |

PLBE |

PLBE |

PLBE |

- |

- |

||

|

40 |

11.43 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

44 |

12.70 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

49 |

14.15 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

9 5/8 |

36 |

244.48 |

8.94 |

PSLB |

- |

- |

- |

- |

- |

|

40 |

10.03 |

PSLBE |

PLBE |

PLBE |

PLBE |

- |

- |

||

|

43.5 |

11.05 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

|

||

|

47 |

11.99 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

53.5 |

13.84 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

58.4 |

15.11 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

10 3/4 |

40.5 |

273.05 |

8.89 |

PSB |

- |

- |

- |

- |

- |

|

45.5 |

10.16 |

PSBE |

- |

- |

- |

- |

- |

||

|

51 |

11.43 |

PSBE |

PSBE |

PSBE |

PSBE |

PSBE |

- |

||

|

55 |

12.57 |

- |

PSBE |

PSBE |

PSBE |

PSBE |

- |

||

|

60.7 |

13.84 |

- |

- |

- |

PSBE |

PSBE |

PSBE |

||

|

65.7 |

15.11 |

- |

- |

- |

PSB |

PSB |

PSB |

||

|

113/4 |

47 |

298.45 |

9.53 |

PSB |

- |

- |

- |

- |

- |

|

54 |

11.05 |

PSB |

- |

- |

- |

- |

- |

||

|

60 |

12.42 |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

||

|

13 3/8 |

48 |

339.72 |

8.38 |

- |

- |

- |

- |

- |

- |

|

54.5 |

9.65 |

PSB |

- |

- |

- |

- |

- |

||

|

61 |

10.92 |

PSB |

- |

- |

- |

- |

|

||

|

68 |

12.19 |

PSB |

PSB |

PSB |

PSB |

PSB |

- |

||

|

72 |

13.06 |

- |

PSB |

PSB |

PSB |

PSB |

PSB |

||

|

16 |

75 |

406 |

11.13 |

PSB |

- |

- |

- |

- |

- |

|

84 |

12.57 |

PSB |

- |

- |

- |

- |

- |

||

|

109 |

16.66 |

P |

P |

P |

- |

P |

P |

||

|

20 |

94 |

508 |

11.13 |

PSLB |

- |

- |

- |

- |

- |

|

30 |

96 |

762 |

16.13 |

PSLB |

- |

- |

- |

- |

- |

|

P - extremo plano; S - hilo redondo corto; L - hilo redondo largo; B - hilos de muelle; Línea e - Extreme; |

|||||||||

API Spec 5CT – Specification 5CT/ISO 11960, Specification for Casing and Tubing, Eighth Edition, Petroleum and natural gas industries-Steel pipes for use as casing or tubing for wells

Mechanical Properties

|

Grade |

Type |

Total elongation under load % |

Yield Strength M pa |

Tensile strength min Mpa |

Hardness |

Specified wall thickness mm |

Allowable hardness variation |

||

|

HRC |

|||||||||

|

min |

max |

HRC |

HBW |

||||||

|

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

- |

- |

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

- |

- |

|

N80

|

1 |

0.5 |

552 |

758 |

689 |

- |

- |

- |

- |

|

Q |

0.5 |

552 |

758 |

689 |

- |

- |

- |

- |

|

|

M65 |

- |

0.5 |

448 |

586 |

586 |

22 |

235 |

- |

- |

|

L80

|

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

|

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

|

|

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

|

|

C90 |

1、2 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

≤12.70 |

3.0 |

|

1、2 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

12.71-19.04 |

4.0 |

|

|

1、2 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

19.05-25.39 |

5.0 |

|

|

1、2 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

≥25.4 |

6.0 |

|

|

C95 |

- |

0.5 |

655 |

724 |

724 |

- |

- |

- |

- |

|

T95 |

1、2 |

0.5 |

655 |

724 |

724 |

25.4 |

255 |

≤12.70 |

3.0 |

|

1、2 |

0.5 |

655 |

724 |

724 |

25.4 |

255 |

12.71-19.04 |

4.0 |

|

|

1、2 |

0.5 |

655 |

724 |

724 |

25.4 |

255 |

19.05-25.39 |

5.0 |

|

|

1、2 |

0.5 |

655 |

724 |

724 |

25.4 |

255 |

≥25.4 |

6.0 |

|

|

P110 |

- |

0.6 |

758 |

965 |

862 |

- |

- |

- |

- |

|

Q125 |

All |

0.65 |

862 |

1034 |

931 |

b |

- |

≤12.70 |

3.0 |

|

All |

0.65 |

862 |

1034 |

931 |

b |

- |

12.71-19.04 |

4.0 |

|

|

All |

0.65 |

862 |

1034 |

931 |

b |

- |

≥19.05 |

5.0 |

|

Chemical Composition

|

Standard |

Grade |

Composition(%) |

||||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

AIs |

||

|

API SPEC 5CT |

J55 |

0.34~0.39 |

0.20~ |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

|

|

≤0.020 |

|

K55· |

||||||||||||

|

N80 |

0.34~0.38 |

0.20~ |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

/ |

/ |

/ |

0.11 |

≤0.020 |

|

|

L80 |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~ |

≤0.20 |

≤0.20 |

/ |

/ |

≤0.020 |

|

|

P110 |

0.26~0.35 |

0.17~ |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~ |

≤0.20 |

≤0.20 |

0.15 |

≤0.08 |

≤0.020 |

|