We are committed to providing one-stop service for steel pipe products to customers around the world.

API SPEC 5CT well casing is utilized in fixing the well wall or down hole, which has wider diameters. API SPEC 5CT can be divided into conductor casing, technical casing and oil casing.

|

API 5CT Casing |

Range 1 |

Range 2 |

Range 3 |

|

4.88~7.62 |

7.62~10.36 |

10.36~14.63 |

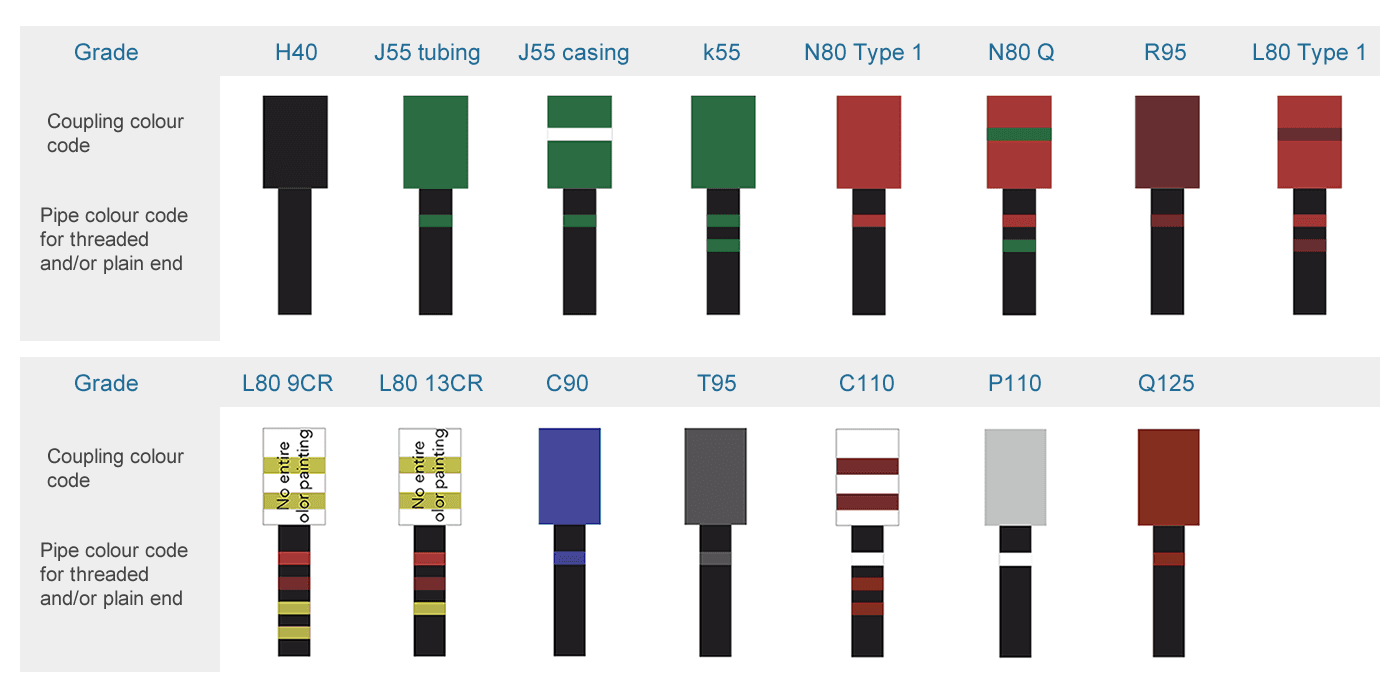

Casing&tubing and their colors:

|

Labels |

OD(mm) |

WT(mm) |

J55/K55 |

N80 |

L80 |

C90/T95 |

P110 |

Q125 |

|

|

4 1/2 |

9.5 |

114.3 |

5.21 |

PS |

- |

- |

- |

- |

- |

|

10.5 |

114.3 |

5.69 |

PSB |

- |

- |

- |

- |

- |

|

|

11.6 |

114.3 |

6.36 |

PSLB |

PLB |

PLB |

PLB |

PLB |

- |

|

|

13.5 |

114.3 |

7.37 |

- |

PLB |

PLB |

PLB |

PLB |

- |

|

|

15.1 |

114.3 |

8.56 |

- |

- |

- |

- |

PLB |

PLB |

|

|

5 |

11.5 |

127 |

5.59 |

PS |

- |

- |

- |

- |

- |

|

13 |

6.43 |

PSLB |

- |

- |

- |

- |

- |

||

|

15 |

7.52 |

PSLBE |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

18 |

9.19 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

21.4 |

11.10 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

23.2 |

12.14 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

24.1 |

12.7 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

5 1/2 |

14 |

139.7 |

6.20 |

PS |

- |

- |

- |

- |

- |

|

15.5 |

6.98 |

PSLBE |

- |

- |

- |

- |

- |

||

|

17 |

7.72 |

PSLBE |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

20 |

9.17 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

23 |

10.54 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

26.8 |

12.7 |

- |

- |

- |

P |

- |

- |

||

|

29.7 |

14.27 |

- |

- |

- |

P |

- |

- |

||

|

32.6 |

15.88 |

- |

- |

- |

P |

- |

- |

||

|

35.3 |

17.45 |

- |

- |

- |

P |

- |

- |

||

|

38 |

19.05 |

- |

- |

- |

P |

- |

- |

||

|

40.5 |

20.62 |

- |

- |

- |

P |

- |

- |

||

|

43.1 |

64.14 |

- |

- |

- |

P |

- |

- |

||

|

6 5/8 |

20 |

168.28 |

7.32 |

PSLB |

|

|

|

|

|

|

24 |

8.94 |

PSLBE |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

28 |

10.59 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

32 |

12.06 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

7 |

20 |

177.8 |

6.91 |

PS |

|

|

|

|

|

|

23 |

8.05 |

PSLBE |

PLBE |

PLBE |

PLBE |

- |

- |

||

|

26 |

9.19 |

PSLBE |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

29 |

10.6 |

|

PLBE |

PLBE |

PLBE |

PLBE |

|

||

|

32 |

11.51 |

|

PLBE |

PLBE |

PLBE |

PLBE |

|

||

|

35 |

12.65 |

|

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

38 |

13.72 |

|

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

7 5/8 |

26.4 |

193.67 |

8.33 |

PSLBE |

PLBE |

PLBE |

PLBE |

- |

- |

|

29.7 |

9.52 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

33.7 |

10.92 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

39 |

12.7 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

42.8 |

14.27 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

45.3 |

15.11 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

47.1 |

15.88 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

8 5/8 |

24 |

219.08 |

6.71 |

PS |

- |

- |

- |

- |

- |

|

28 |

7.72 |

- |

- |

- |

- |

- |

- |

||

|

32 |

8.94 |

PSLBE |

- |

- |

- |

- |

- |

||

|

36 |

10.16 |

PSLBE |

PLBE |

PLBE |

PLBE |

- |

- |

||

|

40 |

11.43 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

44 |

12.70 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

- |

||

|

49 |

14.15 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

9 5/8 |

36 |

244.48 |

8.94 |

PSLB |

- |

- |

- |

- |

- |

|

40 |

10.03 |

PSLBE |

PLBE |

PLBE |

PLBE |

- |

- |

||

|

43.5 |

11.05 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

|

||

|

47 |

11.99 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

53.5 |

13.84 |

- |

PLBE |

PLBE |

PLBE |

PLBE |

PLBE |

||

|

58.4 |

15.11 |

- |

PLB |

PLB |

PLB |

PLB |

PLB |

||

|

10 3/4 |

40.5 |

273.05 |

8.89 |

PSB |

- |

- |

- |

- |

- |

|

45.5 |

10.16 |

PSBE |

- |

- |

- |

- |

- |

||

|

51 |

11.43 |

PSBE |

PSBE |

PSBE |

PSBE |

PSBE |

- |

||

|

55 |

12.57 |

- |

PSBE |

PSBE |

PSBE |

PSBE |

- |

||

|

60.7 |

13.84 |

- |

- |

- |

PSBE |

PSBE |

PSBE |

||

|

65.7 |

15.11 |

- |

- |

- |

PSB |

PSB |

PSB |

||

|

113/4 |

47 |

298.45 |

9.53 |

PSB |

- |

- |

- |

- |

- |

|

54 |

11.05 |

PSB |

- |

- |

- |

- |

- |

||

|

60 |

12.42 |

PSB |

PSB |

PSB |

PSB |

PSB |

PSB |

||

|

13 3/8 |

48 |

339.72 |

8.38 |

- |

- |

- |

- |

- |

- |

|

54.5 |

9.65 |

PSB |

- |

- |

- |

- |

- |

||

|

61 |

10.92 |

PSB |

- |

- |

- |

- |

|

||

|

68 |

12.19 |

PSB |

PSB |

PSB |

PSB |

PSB |

- |

||

|

72 |

13.06 |

- |

PSB |

PSB |

PSB |

PSB |

PSB |

||

|

16 |

75 |

406 |

11.13 |

PSB |

- |

- |

- |

- |

- |

|

84 |

12.57 |

PSB |

- |

- |

- |

- |

- |

||

|

109 |

16.66 |

P |

P |

P |

- |

P |

P |

||

|

20 |

94 |

508 |

11.13 |

PSLB |

- |

- |

- |

- |

- |

|

30 |

96 |

762 |

16.13 |

PSLB |

- |

- |

- |

- |

- |

|

P-Plain end; S-Short round thread; L-Long round thread; B-Buttress thread; E-Extreme line; |

|||||||||

API Spec 5CT – Specification 5CT/ISO 11960, Specification for Casing and Tubing, Eighth Edition, Petroleum and natural gas industries-Steel pipes for use as casing or tubing for wells

Mechanical Properties

|

Grade |

类型Type |

Total elongation under load % |

Yield Strength M pa |

Tensile strength min Mpa |

Hardness |

Specified wall thickness mm |

Allowable hardness variation |

||

|

HRC |

|||||||||

|

min |

max |

HRC |

HBW |

||||||

|

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

- |

- |

|

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

- |

- |

|

N80

|

1 |

0.5 |

552 |

758 |

689 |

- |

- |

- |

- |

|

Q |

0.5 |

552 |

758 |

689 |

- |

- |

- |

- |

|

|

M65 |

- |

0.5 |

448 |

586 |

586 |

22 |

235 |

- |

- |

|

L80

|

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

|

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

|

|

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

|

|

C90 |

1、2 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

≤12.70 |

3.0 |

|

1、2 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

12.71-19.04 |

4.0 |

|

|

1、2 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

19.05-25.39 |

5.0 |

|

|

1、2 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

≥25.4 |

6.0 |

|

|

C95 |

- |

0.5 |

655 |

724 |

724 |

- |

- |

- |

- |

|

T95 |

1、2 |

0.5 |

655 |

724 |

724 |

25.4 |

255 |

≤12.70 |

3.0 |

|

1、2 |

0.5 |

655 |

724 |

724 |

25.4 |

255 |

12.71-19.04 |

4.0 |

|

|

1、2 |

0.5 |

655 |

724 |

724 |

25.4 |

255 |

19.05-25.39 |

5.0 |

|

|

1、2 |

0.5 |

655 |

724 |

724 |

25.4 |

255 |

≥25.4 |

6.0 |

|

|

P110 |

- |

0.6 |

758 |

965 |

862 |

- |

- |

- |

- |

|

Q125 |

All |

0.65 |

862 |

1034 |

931 |

b |

- |

≤12.70 |

3.0 |

|

All |

0.65 |

862 |

1034 |

931 |

b |

- |

12.71-19.04 |

4.0 |

|

|

All |

0.65 |

862 |

1034 |

931 |

b |

- |

≥19.05 |

5.0 |

|

Chemical Composition

|

Standard |

Grade |

Composition(%) |

||||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

AIs |

||

|

API SPEC 5CT |

J55 |

0.34~0.39 |

0.20~ |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

|

|

≤0.020 |

|

K55· |

||||||||||||

|

N80 |

0.34~0.38 |

0.20~ |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

/ |

/ |

/ |

0.11 |

≤0.020 |

|

|

L80 |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~ |

≤0.20 |

≤0.20 |

/ |

/ |

≤0.020 |

|

|

P110 |

0.26~0.35 |

0.17~ |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~ |

≤0.20 |

≤0.20 |

0.15 |

≤0.08 |

≤0.020 |

|