We are committed to providing one-stop service for steel pipe products to customers around the world.

There are three common angles of elbow to use in piping system, 45 degree, 90 degree and 180 degree, these angle types are to turn fluid different into direction, including right angles and return angle, there are also other angles to use, like 60 degree and 180 degree.

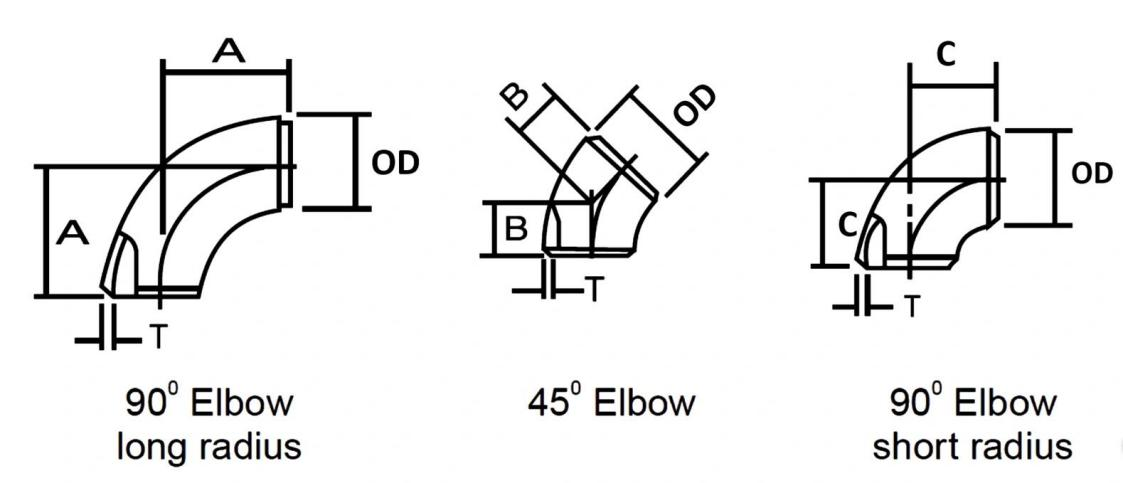

45 Degree Elbow

45 degree elbow changes the flow direction to 45 degrees, it includes long radius 45 degree elbow and short radius 45 degree elbow.

90 Degree Elbow

90 degree elbow changes the flow direction to 90 degrees, it also has long radius and short radius types, 90 degree elbow is the most used elbow..

180 Degree Elbow

180 degree elbow changes the flow direction to 180 degrees.

Types:

Butt Weld Elbow

Butt weld refers to connect pipes and fittings ends by butt welding method, it has ends in beveled to make it easy to weld, beveled ends should be conformed to requirement of ASME B16.25, plain end is offered upon request, BW elbow dimensions can be from 1/2” to 72”, BW weld elbow can be made of both seamless and welded pipe by the process of hot forming that includes bending and forming to shape.

Butt-weld fittings allow for a smooth, flush connection that provides maximum flow, is lower cost elbow, thin wall sizes can be allowed.

Socket Weld Elbow

Socket weld elbow has socket area at end of elbow, it can be inserted a pipe to connect together, the diameter of socket area is matching with the outer diameter of pipe.

Socket connect elbows are easier to weld than butt-weld elbows because the fitting doesn’t need to align perfectly to the pipe. Slip the pipe into the socket and weld, no beveled ends needed.

SW elbows also have 90 degree and 45 degree elbows for selecting, generally, SW elbow is used for small pipe diameter, and have three pressure ratings: Class 3000, 6000 and 9000.

Threaded Elbow

Threaded elbow is similar to the SW elbow in shape, the difference is that threaded elbow has thread inside of elbow end, this type elbow is easier to install and remove, good for pipeline repair and maintenance.

|

Carbon Steel |

ASTM A234 WPB WPC A105 A106 A53 A283-D API5LB A671-CC-70 A515-50 A135-A A179-C,etc |

|

Stainless Steel |

304/304L, 316/316L,316Ti,321,317L,310S,etc |

|

Alloy Steel |

A335-P1,P2 ,P5 ,P11,P12 ,P22,P91,P92,A369-FP1,P2 A250-T1 A209-T1 A213-T2,T9 ,T12 A199-T11,T22, |

|

Duplex Stainless Steel |

S31803(SAF2205),S32750(SAF2507),S31500(3RE60) |

|

Nominal pipe size |

Outside Diameter |

Center to End |

Center to Center |

Back to Faces |

||||||

|

45°Elbows |

90°Elbows |

180°Return |

||||||||

|

H |

F |

P |

K |

|||||||

|

DN |

INCH |

Series A |

Series B |

LR |

LR |

SR |

LR |

SR |

LR |

SR |

|

15 |

1/2 |

21.3 |

18 |

16 |

38 |

- |

76 |

- |

48 |

- |

|

20 |

3/4 |

26.9 |

25 |

16 |

38 |

- |

76 |

- |

51 |

- |

|

25 |

1 |

33.7 |

32 |

16 |

38 |

25 |

76 |

51 |

56 |

41 |

|

32 |

11/4 |

42.4 |

38 |

20 |

48 |

32 |

95 |

64 |

70 |

52 |

|

40 |

11/2 |

48.3 |

45 |

24 |

57 |

38 |

114 |

76 |

83 |

62 |

|

50 |

2 |

60.3 |

57 |

32 |

76 |

51 |

152 |

102 |

106 |

81 |

|

65 |

21/2 |

76.1(73) |

76 |

40 |

95 |

64 |

191 |

127 |

132 |

100 |

|

80 |

3 |

88.9 |

89 |

47 |

114 |

76 |

229 |

152 |

159 |

121 |

|

90 |

31/2 |

101.6 |

- |

55 |

133 |

89 |

267 |

178 |

184 |

140 |

|

100 |

4 |

114.3 |

108 |

63 |

152 |

102 |

305 |

203 |

210 |

159 |

|

125 |

5 |

139.7 |

133 |

79 |

190 |

127 |

381 |

254 |

262 |

197 |

|

150 |

6 |

168.3 |

159 |

95 |

229 |

152 |

457 |

305 |

313 |

237 |

|

200 |

8 |

219.1 |

219 |

126 |

305 |

203 |

610 |

406 |

414 |

313 |

|

250 |

10 |

273.0 |

273 |

158 |

381 |

254 |

762 |

508 |

518 |

391 |

|

300 |

12 |

323.9 |

325 |

189 |

457 |

305 |

914 |

610 |

619 |

467 |

|

350 |

14 |

355.6 |

377 |

221 |

533 |

356 |

1067 |

711 |

711 |

533 |

|

400 |

16 |

406.4 |

426 |

253 |

610 |

406 |

1219 |

813 |

813 |

610 |

|

450 |

18 |

457.2 |

478 |

284 |

686 |

457 |

1372 |

914 |

914 |

686 |

|

500 |

20 |

508.0 |

529 |

316 |

762 |

508 |

1524 |

1016 |

1016 |

762 |

|

550 |

22 |

559 |

- |

347 |

838 |

559 |

Note: |

|||

|

600 |

24 |

610 |

630 |

379 |

914 |

610 |

||||

|

650 |

26 |

660 |

- |

410 |

991 |

660 |

||||

|

700 |

28 |

711 |

720 |

442 |

1067 |

711 |

||||

|

750 |

30 |

762 |

- |

473 |

1143 |

762 |

||||

|

800 |

32 |

813 |

820 |

505 |

1219 |

813 |

||||

|

850 |

34 |

864 |

- |

537 |

1295 |

864 |

||||

|

900 |

36 |

914 |

920 |

568 |

1372 |

914 |

||||

|

950 |

38 |

965 |

- |

600 |

1448 |

965 |

||||

|

1000 |

40 |

1016 |

1020 |

631 |

1524 |

1016 |

||||

|

1050 |

42 |

1067 |

- |

663 |

1600 |

1067 |

||||

|

1100 |

44 |

1118 |

1120 |

694 |

1676 |

1118 |

||||

|

1150 |

46 |

1168 |

- |

726 |

1753 |

1168 |

||||

|

1200 |

48 |

1220 |

1220 |

758 |

1829 |

1219 |

||||

|

ASME |

ANSI B16.9, ANSI B16.28, MSS-SP-43 |

|

DIN |

DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

|

EN |

EN10253-1, EN10253-2 |

|

ASTM A403 |

ASME SA403 – Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings |

|

ASME B16.9 |

Factory-Made Wrought Fittings Buttwelding |

|

ASME B16.25 |

Buttwelding Ends ASME B16.28 – Wrought Steel Short Radius Elbows and Buttwelding Returns |

|

MSS SP-43 |

Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications |