We are committed to providing one-stop service for steel pipe products to customers around the world.

1.Main Products Description

| Core Product | Size | Coating details | Application | |

| FBE, 2FBE, 2LPE,3LPE/PP Coated Pipe | Φ168-1422mm (6-56 inch) | FBE, 2FBE, 2LPE,3LPE/PP | For most oil and gas pipelines and water pipelines | |

| Concrete Weight Coated Pipe | Φ168-1422mm(6-56 inch) | Coating Thickness:35-150mm,Coating Density:2240-3400kg/m3 | For submarine gas pipelines, lakes, cross-section pipelines, etc | |

| Insulation coating pipe | PUF,Polyurethane-coated | Φ168-813mm (6-32 inch) or customized | single-layer insulation jacket pipe, steel-sheathed steel insulation pipe | Land and submarine oil pipelines |

| GSPU | Φ168-813mm (6-32 inch) and larger diameter | Coating Thickness∶30-120mm | Deepwater oil pipelines, with a maximum depth of more than 1,500 meters. | |

|

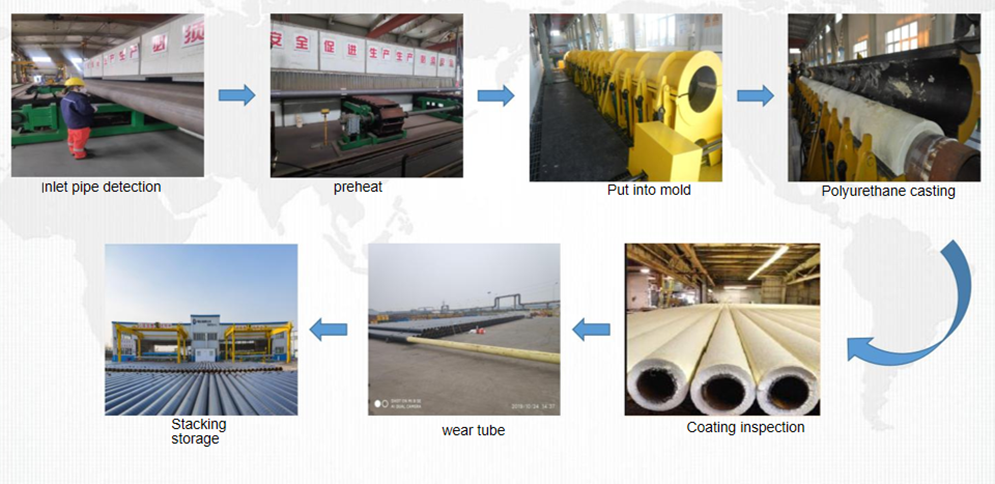

Polyurethane casting process |

||||

| Silica airgel felt steel sheathed steel thermal insulation process | Submarine double-layer insulated pipe | |||

2.Overseas general engineering contracting and construction, large offshore and coastline on-site construction experience

In the past five years, more than 500,000 tons of steel pipes have been supplied to offshore oil and gas projects;

In 2004, we completed the 3LPE+CWC coating task for China’s longest submarine pipeline—400km;

In 2011/2019, the coating task of FJC, the deepest submarine pipeline in China, was completed—1500m water depth;

The company is China's leading integrated pipeline anti-corrosion, thermal insulation, concrete counterweight and FJC business

enterprise.

It undertakes the design, consulting and on-site technical services of offshore oil and gas field development projects, submarine pipelines, submarine cables, oil and gas processing land terminals, pressure vessels, marine structure shipping and offshore transportation and installation. It has 1500 meters water depth offshore oil and gas field development projects and floating Design capabilities of production systems and simple facilities for offshore oil and gas field development.

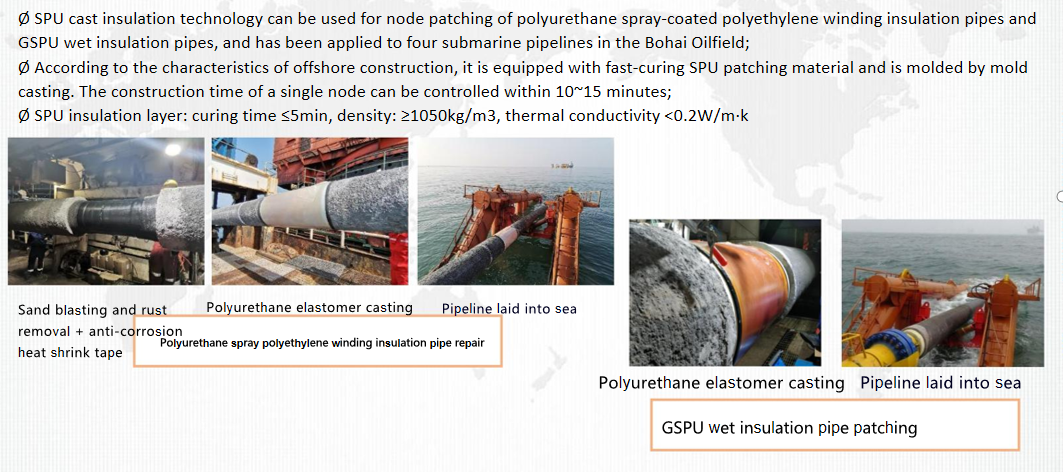

Submarine pipe node SPU insulation

Marine pipeline intersection isolation protective cover

Cooperated with CNOOC Co., Ltd. to develop a new submarine pipeline cross-crossing protection treatment technology and its products, and successfully demonstrated it in the Luda 5-2N project

The application provides a new, efficient and low-cost solution for the cross-crossing protection treatment of submarine pipelines in the Bohai Oilfield.

conducting in-depth research on product serialization and promoting the large-scale application of new technologies.

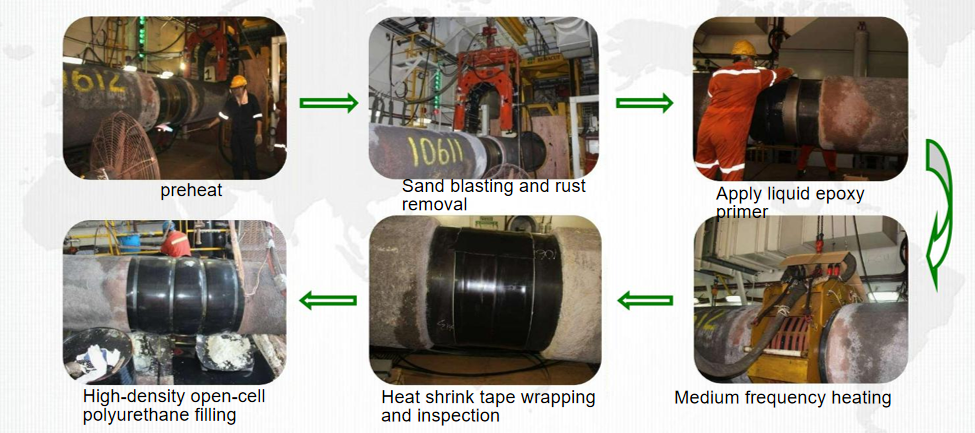

Node repair process

Steel pipe specifications: Φ114-Φ1422mm (4-56 inch), coating type: LE+HSS/LE+HSS+PU/FBE+HSS,

Capacity: 2km/24h (taking Φ559mm as an example).

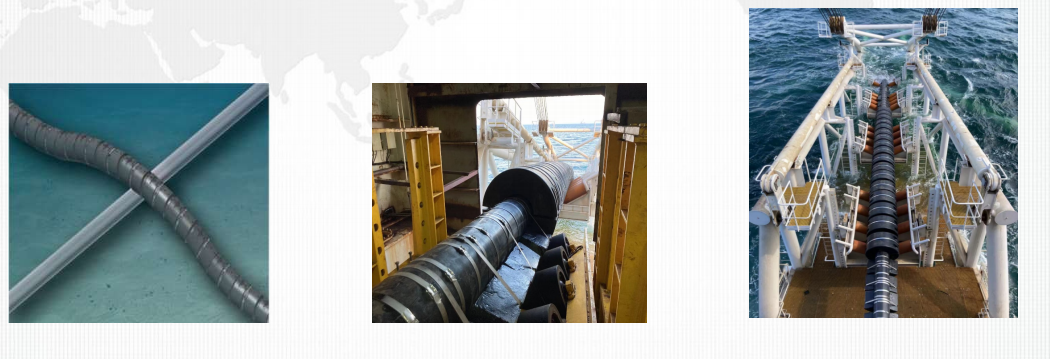

Vortex induced vibration suppression device/spiral strakes

The company has developed a series of products with different materials (PU, PP) and different application scenarios. The application water depth is up to 1,500 meters, and the applicable pipe diameters range from 4.5 inches to 16 inches.

Suppression efficiency ≥90%, drag force coefficient ≤1.6.

SPU wet insulation for underwater production facilities

In order to coordinate and solve key issues such as material adaptation, complex structure mold design, on-site process optimization control, and construction capacity improvement, a complete SPU wet insulation technology system for underwater production facilities has been formed.

1. The coating has a temperature resistance level of 90°C and a maximum applicable water depth of 1500m;

2. The technology and coating meet the requirements of API 17U, ISO12736 and other standards;

3. Obtain DNV certification report for materials and coatings;

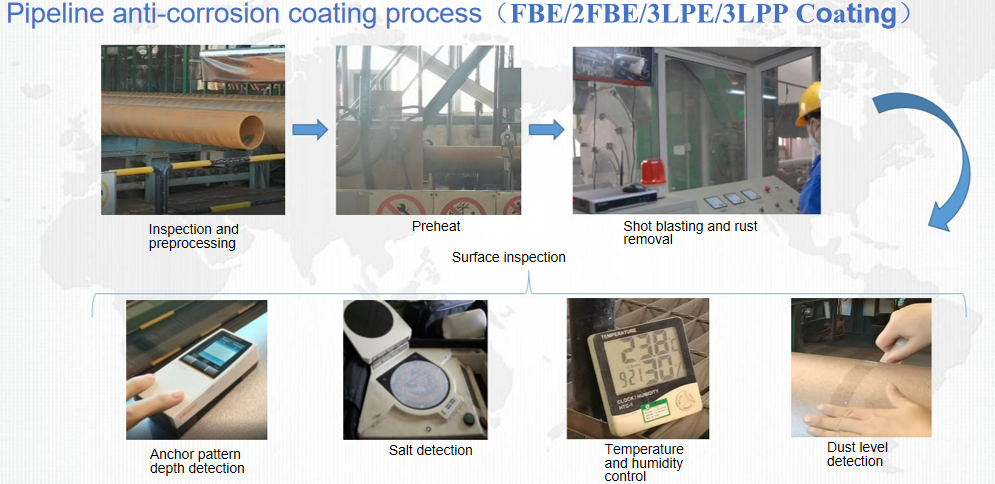

Pipe diameter:Φ168-1422mm (6-56 inch);Coating type:FBE, 2FBE, 2LPE, 3LPE/PP

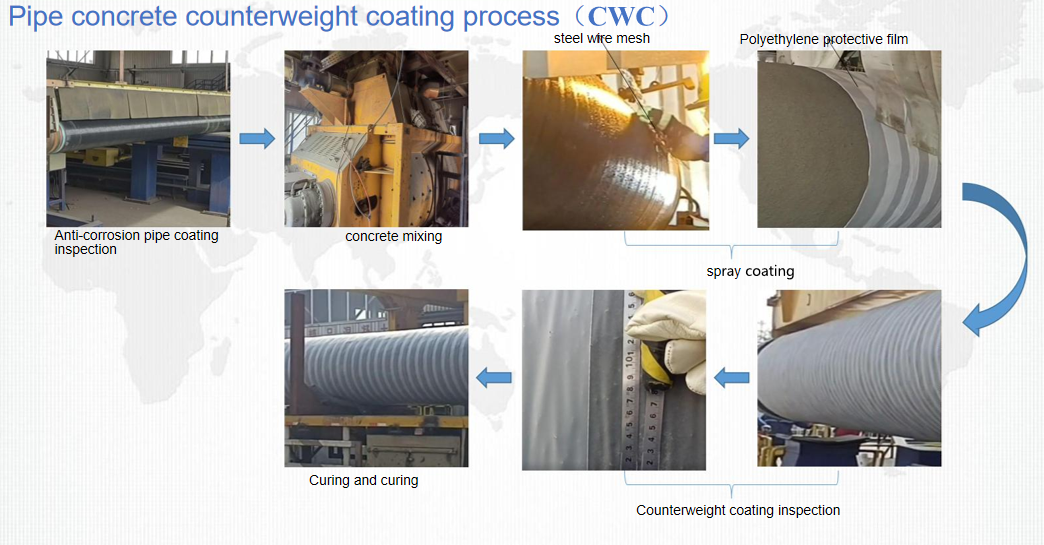

Pipe concrete counterweight coating process(CWC)

Pipe diameter:Φ168-1422mm(6-56 inch),Coating thickness: 35-150mm,Coating density: 2240-3400kg/m3,

Thermal insulation coating-a. Polyurethane spray polyethylene extrusion coating process (PUF)

Steel pipe specifications: Φ168-813mm (6-32 inch), which can also be customized according to customer needs.

Coating type: single layer insulation jacket pipe, steel jacket steel insulation pipe

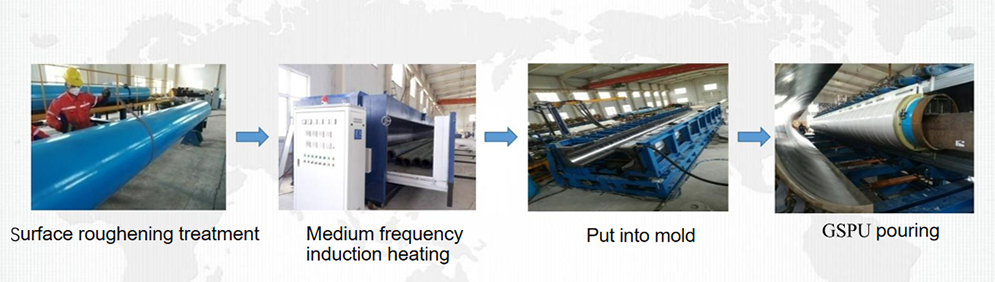

Steel pipe specifications:Φ168-813mm (6-32 inch), coating thickness:30-120mm

Thermal insulation coating-d. Silica airgel felt steel sheathed steel thermal insulation process