Sharing China-Made with Global Customers

In the field of fluid mechanics and piping design, understanding the absolute roughness of carbon steel pipe is crucial for accurate flow calculations and efficient system design. Absolute roughness refers to the average height of surface irregularities inside a pipe, typically measured in millimeters or inches. These microscopic imperfections significantly affect the frictional resistance of the pipe, which in turn impacts pressure drop, flow rate, and overall energy consumption.

Absolute roughness is a fundamental parameter in hydraulic engineering. It quantifies the texture of the pipe’s internal surface. Even though carbon steel pipes may appear smooth to the naked eye, microscopic peaks and valleys exist due to manufacturing processes, corrosion, or wear over time. These irregularities create additional resistance to fluid flow, which must be accounted for in engineering calculations.

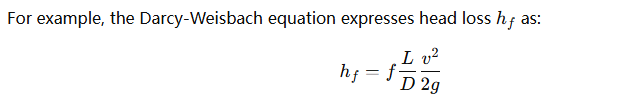

For carbon steel pipes, the typical absolute roughness ranges between 0.045 mm and 0.09 mm depending on the pipe grade, finish, and age. Engineers use this value in formulas such as the Darcy-Weisbach equation to estimate head loss in a piping system accurately.

The absolute roughness of carbon steel pipe directly influences the friction factor, a key component in calculating pressure drop and flow rate. In laminar flow, roughness has minimal effect, but in turbulent flow—which is common in industrial applications—the impact is significant. Using an incorrect roughness value can lead to underestimating friction losses, causing pump oversizing, excessive energy consumption, and potential system inefficiency.

Where the friction factor fff depends on both Reynolds number and the absolute roughness of carbon steel pipe. Accurate roughness values are therefore essential for precise engineering calculations and cost-effective design.

Several factors can influence the absolute roughness of carbon steel pipes:

1. Manufacturing Process: Seamless pipes generally have lower roughness than welded pipes.

2. Corrosion and Scaling: Over time, internal surfaces can degrade, increasing roughness.

3. Cleaning and Maintenance: Well-maintained systems retain lower roughness, reducing friction losses.

Understanding these factors helps engineers predict how the pipe will perform throughout its lifecycle.

· Pump Selection: Accurate roughness data ensures proper sizing of pumps and reduces operational costs.

· Energy Efficiency: Lower friction losses improve energy efficiency in fluid transport.

· System Longevity: Reducing turbulent friction and pressure fluctuations extends the life of the piping system.

In addition, designers often refer to standard tables for absolute roughness of carbon steel pipe values when performing preliminary system calculations. For instance, ASTM standards provide roughness ranges for different pipe grades, ensuring reliability and consistency.

The absolute roughness of carbon steel pipe is a critical parameter in fluid flow calculations. By understanding and correctly applying this value, engineers can design more efficient piping systems, reduce energy consumption, and prevent operational issues. Ignoring or underestimating pipe roughness can lead to costly mistakes, making it essential to include in all hydraulic and fluid mechanics calculations.