Applications in Industry

· Black Iron Pipe: Gas distribution in residential/commercial buildings, fire suppression lines.

· Carbon Steel Pipe: Pipelines for oil and gas, steam systems, boiler piping, structural frameworks, and industrial machinery.

Sharing China-Made with Global Customers

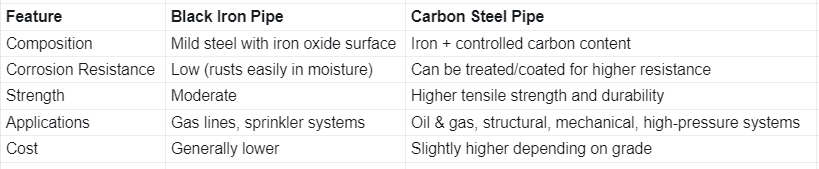

When selecting materials for piping systems, engineers and contractors often weigh black iron vs carbon steel pipe. While these two materials may look similar on the surface, their chemical composition, mechanical properties, and intended applications differ significantly. Understanding the differences is crucial for making informed decisions in construction, plumbing, gas distribution, and industrial projects.

Black iron pipe is a low-grade, ungalvanized steel pipe commonly used for gas and fire sprinkler systems. The “black” appearance comes from the iron oxide formed during manufacturing.

· Strengths: Cost-effective, good pressure resistance, suitable for non-potable gas transmission.

· Limitations: Susceptible to rust and corrosion in wet environments, not recommended for potable water.

Carbon steel pipe is manufactured by alloying iron with varying amounts of carbon, usually between 0.05%–2%. This composition gives it superior tensile strength and durability compared to black iron pipe.

· Strengths: High strength-to-weight ratio, customizable grades (low, medium, high carbon), wide industrial usage including oil, petrochemical, and power generation.

· Limitations: Requires protective coatings or linings to prevent corrosion in certain environments.

In short, when comparing black iron vs carbon steel pipe, carbon steel typically offers better performance and longer lifespan, while black iron is valued for its affordability in low-moisture, low-corrosion settings.

· Black Iron Pipe: Gas distribution in residential/commercial buildings, fire suppression lines.

· Carbon Steel Pipe: Pipelines for oil and gas, steam systems, boiler piping, structural frameworks, and industrial machinery.

Your decision between black iron and carbon steel pipe should depend on:

1. Operating Environment – High humidity or corrosive settings favor carbon steel with coatings.

2. Budget Considerations – Black iron pipe offers a cheaper alternative for dry indoor systems.

3. Pressure & Load Requirements – Carbon steel is the preferred choice for heavy-duty, high-pressure operations.

The debate of black iron vs carbon steel pipe is less about which is universally “better” and more about matching material properties to project requirements. For gas lines and budget-conscious projects, black iron pipe may suffice. For high-strength, long-lasting, and corrosion-resistant applications, carbon steel is the superior choice.

If you are looking for high-quality carbon steel seamless pipe, feel free to contact us. We will help you find the most suitable solution and the best products for your project.