Sharing China-Made with Global Customers

Cold drawn seamless steel pipes are essential components in various industries due to their high dimensional accuracy, superior surface finish, and excellent mechanical properties. But what exactly are they, and how are they produced?

Cold drawn seamless steel pipes (CDS) are precision tubes used for mechanical structures, hydraulic equipment, and other applications requiring high precision and surface quality. These pipes offer enhanced machinability, uniform tolerances, and higher strength compared to hot-rolled products.

The production of CDS involves several key stages:

1. Pickling of Steel Pipe Blanks: Removes oxides, rust, and impurities from the surface.

2. Heating Treatment: The billet is heated to ensure smooth subsequent processing.

3. Cold Rolling Processing: Billets are rolled to transform them into seamless tubes with precise specifications.

4. Heat Treatment: Reduces stress and improves mechanical properties.

5. Surface Treatment: Enhances finish by removing impurities and oxides.

6. Testing and Packaging: Ensures quality and readiness for storage and transport.

| Step | Description |

|---|---|

| Pickling | Removes surface impurities |

| Heating Treatment | Prepares billets for cold rolling |

| Cold Rolling | Achieves precise specifications |

| Heat Treatment | Relieves stress, improves properties |

| Surface Treatment | Improves finish |

| Testing & Packaging | Ensures quality and prepares for delivery |

Excellent Surface Finish: Minimized surface roughness and oxide layers.

High Dimensional Accuracy: Precise control over dimensions ensures perfect fitting.

Uniform Structure: Fine grains enhance mechanical properties and corrosion resistance.

Versatile Application: Used across industries like automotive, aerospace, and petrochemical. Cold Drawn Seamless Tubes Image suggestion: A high-resolution image showcasing the smooth finish and uniform diameter of cold drawn seamless tubes.

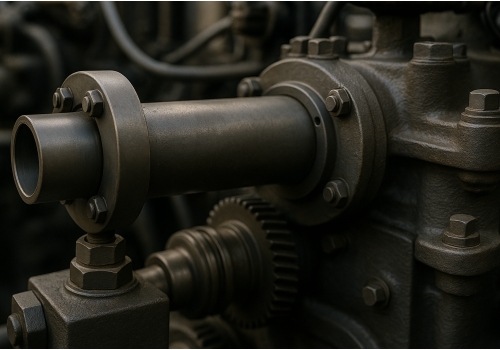

Machinery Manufacturing: Used in components like transmission shafts and gears.

Automobile Parts: Integral in chassis, exhaust, and braking systems.

Aerospace: Essential for engines and fuselage components.

Petrochemical Industry: Ideal for fluid transport pipelines. Application in Machinery Image suggestion: A vibrant image showing cold drawn seamless tubes in a complex machinery assembly.

This process is vital for enhancing material properties:

1. Annealing: Improves plasticity and reduces hardness.

2. Normalizing: Enhances machinability and refines grain.

3. Hardening: Increases hardness and wear resistance.

4. Tempered: Achieves required plasticity and toughness.

5. Chemical Treatment: Improves surface properties like hardness and corrosion resistance.

6. Solution Treatment: Prepares alloy for further hardening.

Ensuring the quality of CDS involves:

· Appearance Inspection: Assesses surface quality, dimensions, and form.

· Chemical Composition Analysis: Confirms compliance with standards.

· Mechanical Performance Testing: Evaluates strength and toughness.

· Penetration Testing: Detects defects like cracks and bubbles. Quality Control Inspection Image suggestion: A detailed image of quality control engineers inspecting seamless tubes in a lab setting.

Cold drawn seamless steel pipes play a crucial role in modern industries, offering unmatched precision, strength, and reliability. Their wide range of applications and superior properties make them indispensable in sectors demanding high performance and dependability. By understanding their production, features, and applications, industries can better leverage the benefits of these essential components.