Sharing China-Made with Global Customers

Spiral welded steel pipe is a critical component in industries such as oil and gas, water transportation, and structural engineering. Due to its cost-efficiency, high strength, and adaptability, spiral weld steel pipe is widely used in demanding environments. However, maximizing the service life of steel pipe requires a combination of high-quality materials, advanced manufacturing, corrosion protection, and proper maintenance.

This guide explores proven strategies to enhance the durability and performance of spiral welded steel pipe, ensuring long-term reliability in various applications.

The service life of steel pipe heavily depends on the quality of raw materials. Key considerations include:

· API 5L (X42-X80): High-strength steel grades for oil and gas pipelines.

· ASTM A252: Used in structural piling applications.

· Stainless Steel (304/316): For highly corrosive environments (e.g., chemical processing).

· Micro-alloyed steels with chromium, copper, or nickel improve corrosion resistance.

· Weathering steel (Corten) forms a protective rust layer, reducing maintenance needs.

The production process of spiral weld steel pipe directly impacts its structural integrity. Key advancements include:

· Submerged Arc Welding (SAW): Ensures deep penetration and high-quality welds.

· Laser and Automated Welding: Reduces human error and improves consistency.

· Relieves residual stresses from welding, preventing cracks and deformations.

· Improves toughness, especially in high-pressure applications.

· Ultrasonic Testing (UT): Detects internal flaws.

· Radiographic Testing (RT): Identifies weld defects.

· Hydrostatic Testing: Ensures pressure resistance before deployment.

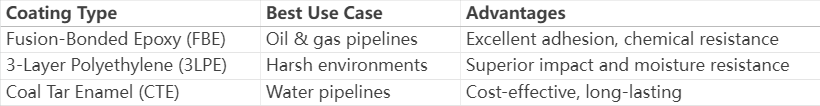

Corrosion is the leading cause of failure in spiral welded steel pipe. Effective protection methods include:

· Sacrificial Anodes (Galvanic CP): Zinc or magnesium anodes corrode instead of the pipe.

· Impressed Current CP: Uses an external power source for large-scale protection (e.g., underground pipelines).

· Cement Mortar Lining: Prevents rust in water pipelines.

· Polyurethane Linings: Used in abrasive slurry transport.

Improper installation can drastically reduce the service life of steel pipe. Best practices include:

· Use sand bedding to prevent sharp rocks from damaging coatings.

· Ensure proper pipe alignment to avoid stress concentrations.

· Use padding during transportation to prevent scratches.

· Follow proper lifting techniques with nylon slings instead of metal chains.

Regular maintenance is crucial for detecting issues before they escalate.

· Visual Checks: Look for coating damage, rust spots, or dents.

· In-Line Inspection (ILI) Tools: "Smart pigs" detect internal corrosion and cracks.

· Patch Welding: For minor cracks.

· Composite Sleeve Repairs: Reinforces damaged sections without excavation.

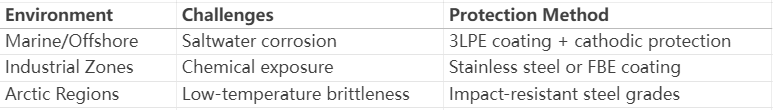

Different environments require tailored approaches:

By implementing high-quality materials, advanced welding techniques, corrosion protection, proper installation, and regular maintenance, the service life of steel pipe can be significantly extended. Whether used in oil pipelines, water systems, or structural projects, spiral weld steel pipe remains a durable and cost-effective solution when properly maintained.

For more industry insights on spiral welded steel pipe, follow our engineering updates and best practice guides!