Vision/Value: Pragmatism, Integrity, Passion

When choosing structural steel tubes for construction, engineering, or industrial applications, two common ASTM standards dominate the market: ASTM A1085 and ASTM A500. Both are widely used, but they have key differences in strength, tolerances, and applications.

If you're deciding between ASTM A1085 vs ASTM A500, this guide will compare their properties, benefits, and ideal use cases—helping you select the best option for your project.

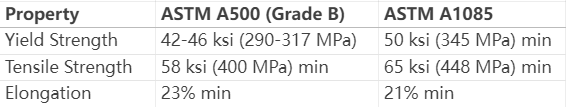

· ASTM A500: A traditional carbon steel tube with a wider chemical composition range. It is available in Grades A, B, C, and D, with varying yield and tensile strengths.

· ASTM A1085: A newer, high-performance specification with tighter chemical controls and enhanced mechanical properties. It is designed for improved weldability and structural integrity.

Key Takeaway: ASTM A1085 offers higher strength and better performance in critical structural applications.

· ASTM A500: Allows looser tolerances, which can lead to more variation in wall thickness and straightness.

· ASTM A1085: Has stricter tolerances, ensuring more consistent dimensions—ideal for precision construction.

✔ You need higher strength-to-weight ratio (better for seismic and high-load structures).

✔ Your project requires tighter dimensional control (e.g., modular construction, bridges).

✔ You want better weldability and ductility (reduces cracking risk).

✔ Your project has lower budget constraints (A500 is typically cheaper).

✔ You don’t need the highest strength (e.g., non-critical supports, fencing).

✔ You’re working with standard structural applications where extreme precision isn’t required.

· Seismic-resistant buildings (due to higher ductility)

· Bridges & highway structures (better fatigue resistance)

· Modular construction (tighter tolerances ensure fit-up accuracy)

· General construction frameworks

· Handrails, fences, and non-load-bearing structures

· Industrial storage racks & support beams

While ASTM A1085 is generally 10-20% more expensive than A500, it offers:

✅ Reduced material usage (higher strength means less steel needed).

✅ Lower labor costs (easier welding and fabrication).

✅ Long-term durability (better corrosion resistance in some environments).

For high-performance projects, the extra cost of A1085 can be justified. However, for basic structural needs, A500 remains a cost-effective choice.

The decision between ASTM A1085 vs ASTM A500 depends on:

· Project requirements (strength, precision, weldability).

· Budget constraints (A500 is cheaper, but A1085 may save long-term costs).

· Regulatory & safety standards (some codes now prefer A1085 for critical structures).

If you need maximum performance and durability, ASTM A1085 is the superior choice. For general-purpose applications, ASTM A500 remains a reliable and economical option.

Need High-Quality Structural Steel Tubes? Contact us today to find the perfect solution for your project!