Sharing China-Made with Global Customers

You face extreme pressure and temperature challenges in your heavy industry projects. Weak pipes lead to costly failures and safety risks. We provide the solution that guarantees safety and longevity. Alloy steel seamless pipes are metal tubes formed without welding gaps, fortified with elements like Chromium and Molybdenum. They offer superior resistance to high temperatures, high pressure, and corrosion compared to standard carbon steel, making them essential for critical energy and construction infrastructure.

Many suppliers offer general steel options, but few understand the intricate needs of complex EPC projects. You need to know exactly why these specific pipes are the backbone of modern engineering.

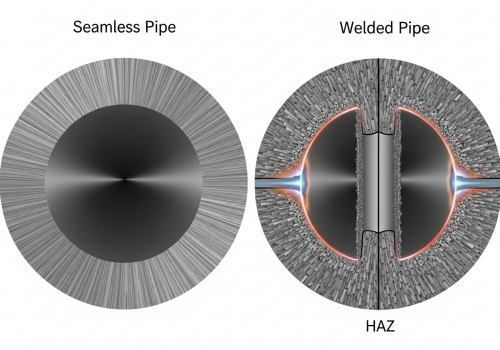

Welding seams are often the first point of failure in high-stress environments. You need a structure that eliminates this risk completely to ensure the safety of your operation. The seamless manufacturing process creates a uniform hull with no weak points. By adding alloys like Nickel and Vanadium, these pipes gain exceptional mechanical strength and thermal stability tailored for extreme conditions.

I want to explain why we at Centerway Steel recommend these pipes for your most difficult projects. The main difference lies in the production method and the chemical composition. A seamless pipe is made from a solid round billet. We heat it and push or pull it over a form until the pipe takes shape. This means there is no seam. A seam is always the weakest part of a pipe. Under high pressure, a seam can split. A seamless pipe distributes the pressure evenly around the circumference. However, the structure is only half the story. The "Alloy" part is just as important. We add specific elements to the steel to change how it behaves. If you need the pipe to resist rust in a chemical plant, we add Chromium. If the pipe must stay strong inside a hot boiler, we add Molybdenum. If you are building an LNG tank that is freezing cold, we add Nickel. This combination makes alloy steel seamless pipes much more expensive than standard welded carbon pipes. The cost can be two to five times higher. But you must think about the total cost of ownership. If a cheaper pipe bursts, your plant stops working. The repair cost and lost time are much higher than the price of the better pipe. Here is a simple comparison of why you might choose one over the other:

| Feature | Ordinary Carbon Steel Pipe | Seamless Alloy Steel Pipe | Benefit for Buyer |

|---|---|---|---|

| Structure | Welded or Seamless | Seamless | No weak points, higher safety factor. |

| Tensile Strength | 370-600 MPa | 550-1000 MPa (e.g., 42CrMo) | Can use thinner walls for same pressure. |

| Temp Limit | ≤350℃ | Up to 600℃ (e.g., 15CrMoG) | Essential for power plants and refining. |

| Corrosion | Needs coating | Self-contained resistance | Lower maintenance costs over time. |

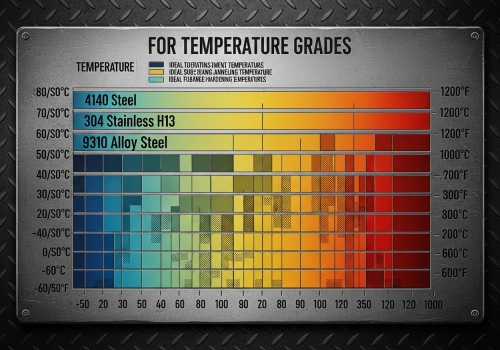

Choosing the wrong grade can lead to disaster, even if the pipe is seamless. You must match the material properties to your specific operating environment to avoid early replacement. Common grades range from Chromium-Molybdenum series for high heat to Nickel-based alloys for cryogenics. Selecting the right grade ensures your alloy steel seamless pipes last longer and perform better under specific stresses.

In my experience serving global EPC companies, I see many buyers confused by the number of steel grades. It is crucial to select the exact grade for the job. You do not want to pay for a high-nickel alloy if you only need basic heat resistance. Conversely, using a basic grade in a corrosive environment will cause leaks very quickly. We usually divide these materials into three main groups based on what they do best. First, we have the Chromium-Molybdenum series. These are the workhorses for high heat. Grades like 15CrMo and 12Cr1MoV are standard for boiler tubes and power stations. They hold their shape and strength even when they are very hot. Second, we have the Stainless Steel series. Grades like 304 and 316L are famous for resisting acid and chemicals. If your project involves food processing or seawater, these are necessary. Third, for the most extreme conditions, we use Nickel-based alloys like Inconel. These are for things like aircraft engines or nuclear components. They are very expensive but perform where other metals melt or fail. We can look at the specific applications for these grades below:

| Material Category | Typical Grade | Main Characteristic | Best Application Scenario |

|---|---|---|---|

| Cr-Mo Steel | 15CrMo | Heat resistant up to 550℃ | Boiler tubes, petroleum cracking. |

| Cr-Mo-V Steel | 12Cr1MoV | High pressure resistant | Power station high-temp pipelines. |

| Stainless Steel | 316L | Molybdenum added | Seawater environments, chemical plants. |

| Nickel Alloy | Inconel 625 | 1100℃ High Temp | Aerospace, Nuclear fuel transport. |

Managing multiple suppliers for different pipe specifications causes delays and quality gaps. You need a partner who integrates production, testing, and logistics to save you time and money. From oil refineries to power plants, alloy steel seamless pipes form the arteries of infrastructure. A reliable supplier ensures strict adherence to ISO and API standards through rigorous third-party inspections like SGS.

As a Purchasing Manager, you know the headache of logistics. You have pipes coming from one factory, valves from another, and fittings from a third. If one is late, the whole project stops. This is why Centerway Steel focuses on integration. Since 1996, we have built a system that handles everything. We see these pipes used everywhere. In the Oil and Gas industry, they are used for drill pipes and casings because they must survive deep underground. In the Energy sector, specifically power plants, they carry high-pressure steam. We even supply them for mechanical uses, like hydraulic cylinders in heavy machinery, because they resist wear and tear. Quality control is the most important part of this process. It is not enough to just make the pipe. We must prove it is good. We use third-party inspectors like SGS, BV, and TUV. We hold certifications like ISO 9001 and API 5CT. When you buy from us, you are not just buying steel. You are buying the certainty that the pipe will not fail. We serve clients like Shell and CNPC, so we understand the strict paperwork and testing required for big projects. Here is where we typically supply these products:

| Industry Sector | Typical Application | Key Requirement |

|---|---|---|

| Oil & Gas | Well casing, Drill pipe, Transport | High tensile strength, API 5CT compliance. |

| Chemical | Reactors, Hydrocracking units | Corrosion resistance against acids/alkalis. |

| Power Gen | Supercritical units, Boilers | Extreme heat resistance (>600℃). |

| New Energy | Hydrogen transport, Wind towers | Hydrogen embrittlement resistance, Structural stability. |

We combine global standards with efficient manufacturing to provide reliable, high-performance piping solutions. Contact Centerway Steel today to secure the best materials for your next project.