Sharing China-Made with Global Customers

Sourcing high-quality structural materials often feels like a battle between cost and precision. You might struggle to find a supplier who truly understands the technical nuance of changing shapes. I know this pain well. The process of transforming a round pipe to square pipe involves cold processing seamless circular tubes into square or rectangular sections. This technique increases the section modulus and bending resistance while saving material. It offers a superior alternative to welded pipes for structural integrity in heavy construction projects.

Many buyers overlook the specific method used for this conversion, but understanding it is the key to project success.

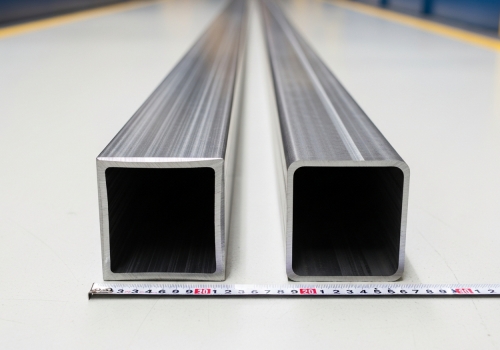

We often see clients confused about why one square pipe costs more than another. The difference lies entirely in the manufacturing technique used to shape the steel. The two main methods are cold drawing and roll forming. Cold drawing pulls the pipe through a mold for sharp corners and high precision. Roll forming uses rollers to squeeze the pipe into shape, offering high efficiency and lower costs but with more rounded corners.

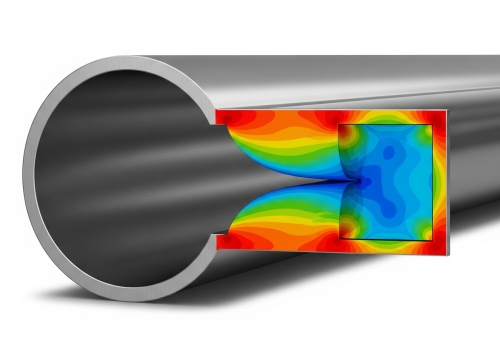

At Centerway Steel, we have handled thousands of tons of material, and we see that the round pipe to square pipe process relies on metal plasticity. The core principle is simple but strict. We deform the steel at room temperature. We follow the law that the perimeter of the neutral line remains constant. This means the length of the middle layer of the steel wall does not change much, but the cross-section shape does. When we look at the specific methods, we need to think critically about your project needs.

Cold Drawing: This is for the perfectionist. We pull the seamless round pipe through a mold that is harder than the pipe itself. The mold has the exact square shape you want. This process gives you very high dimensional accuracy. The corners are sharp and almost right angles. However, it is slower and costs more. If we do not control it well, there is a risk of surface scratches.

Roll Forming (Extrusion): This is for the volume buyer. We push the round pipe through a series of rollers. These rollers gradually squeeze the round shape into a square one. It is fast, efficient, and wastes almost no material. The downside is the corners. They have a larger radius (R-angle), so they are not as sharp as cold-drawn pipes. Here is a simple breakdown to help you compare:

| Feature | Cold Drawing | Roll Forming (Extrusion) |

|---|---|---|

| Precision | Very High | Standard |

| Corner Shape | Sharp, Right Angles | Rounded (Larger R-Angle) |

| Production Speed | Slower | Fast |

| Cost | Higher | Lower |

| Surface Risk | Potential for scratches | Smooth |

| Ideal Use | Precision machinery, Furniture | Structural beams, Large volume projects |

Knowing the theory is one thing, but seeing the production line is another. Quality control during the shaping process determines the lifespan of your final structure. The workflow includes material selection, acid pickling to remove oxides, the actual forming process, and heat treatment to relieve stress. Each step, especially mold design and lubrication, is critical to preventing surface scratches and ensuring the structural integrity of the final product.

I want to take you deeper into the workflow because this is where many suppliers fail. A round pipe to square pipe project is only as good as the preparation. First, we select high-quality seamless round pipes as the "mother" material. If the mother pipe has flaws, the square pipe will fail.

Preparation and Pre-treatment: We do not just start bending metal. We must cut the pipe and then pickle it. Acid pickling removes oxides and rust from the surface. This is vital. If the surface is dirty, it will ruin the mold and the pipe surface during deformation.

The Forming Process: Whether we use cold drawing or roll forming, control is everything. We have to manage the deformation amount. If we deform it too fast, the steel cracks. We also need excellent lubrication. Good lubrication reduces friction and heat. It protects the surface of the pipe and extends the life of our molds.

Post-Processing: After the pipe is square, we are not done. The metal now has internal stress. It is "tense" from being bent. We often perform heat treatment, like annealing, to relax the metal. Then, we straighten it and cut the ends to be clean. Critical Technologies:

· Mold Design: The accuracy of the mold dictates the accuracy of the pipe.

· Simulation: We use software to simulate the process before we run it. This helps us optimize parameters. Here is the flow we follow to ensure the quality you expect in Germany:

1. Raw Material Inspection (Checking the Mother Pipe)

2. Surface Cleaning (Acid Pickling)

3. Forming (Cold Draw or Roll)

4. Heat Treatment (Stress Relief)

5. Final Inspection (SGS/BV Standards)

You have the specs, but do they match the application? Choosing the wrong type of tube for a specific load-bearing environment can lead to costly failures. Seamless square pipes derived from round ones offer better uniformity and fatigue resistance than welded options. They are essential in high-stress environments like offshore platforms, heavy machinery, and high-rise steel structures where structural failure is not an option. When I talk to engineers in the EPC sector, I always emphasize the difference between these seamless converted pipes and standard welded square pipes. The round pipe to square pipe conversion creates a product with no weld seam. A weld seam is often the weakest point in a pipe. By eliminating it, we improve the pressure-bearing capacity and fatigue resistance significantly.

Structural Applications: In the construction industry, especially for high-rise buildings and large span roofs like airports, safety is the priority. We recommend these pipes for trusses, purlins, and wall frames. The combination of cold-formed square pipes and H-beams is currently a very popular solution in the industry. It balances weight and strength perfectly.

Mechanical and Industrial Use: For heavy machinery, like cranes or conveyor belt supports, the pipe must withstand constant vibration. A seamless square pipe handles this much better than a welded one. We also supply these for the automotive and shipbuilding industries, where every kilogram of weight saved matters.

Aesthetic Uses: Sometimes, looks matter. Cold-drawn pipes have sharp, clean corners. This makes them perfect for high-end furniture, architectural railings, and decorative facades. To help you decide for your next procurement list, consider this guide:

| Industry | Recommended Process | Reason |

|---|---|---|

| Construction (General) | Roll Forming | Cost-effective for large volumes; R-angle is acceptable. |

| Precision Machinery | Cold Drawing | Requires tight tolerances and perfect fit. |

| Architectural Decor | Cold Drawing | Aesthetics; sharp lines look better. |

| Heavy Load Structure | Seamless (Either) | Must avoid welded seams for safety. |

| Offshore/Oil & Gas | Seamless (Either) | High resistance to pressure and fatigue is non-negotiable. |

Converting round pipes to square shapes offers superior strength and versatility. Choose roll forming for efficiency or cold drawing for precision. Centerway Steel provides both solutions with top-tier quality control.