Sharing China-Made with Global Customers

Boiler tube leaks represent one of the most common and costly failures in steam generation systems. Even small boiler tube leaks can lead to significant operational disruptions, reduced efficiency, and substantial repair expenses. In severe cases, they may cause catastrophic equipment failure and safety hazards. This comprehensive guide examines all aspects of boiler tube leaks, providing plant operators, maintenance engineers, and facility managers with the knowledge needed to effectively address this persistent challenge.

Boiler tube leaks typically originate from several fundamental mechanisms:

· Corrosion-induced leaks:

o Oxygen pitting corrosion (especially in feedwater systems)

o Acidic corrosion from low pH water

o Caustic gouging from high pH concentrations

o Galvanic corrosion in mixed-metal systems

· Erosion-related failures:

o Fly ash erosion in coal-fired units

o Steam cutting at tube bends

o Turbine blade erosion in HRSG systems

· Thermal stress failures:

o Thermal fatigue cracking

o Creep damage in high-temperature superheaters

o Short-term overheating incidents

· Mechanical and operational causes:

o Vibration-induced fatigue

o Improper tube expansion during installation

o Water hammer events

Certain boiler components are particularly prone to developing boiler tube leaks:

1. Waterwall tubes: Subject to corrosion, pitting, and fireside deposits

2. Superheater and reheater sections: Vulnerable to creep and thermal fatigue

3.Economizer tubes: Prone to oxygen pitting and flow-accelerated corrosion

4. Mud drum and lower headers: Affected by under-deposit corrosion

5. Tube bends and welds: Stress concentration areas

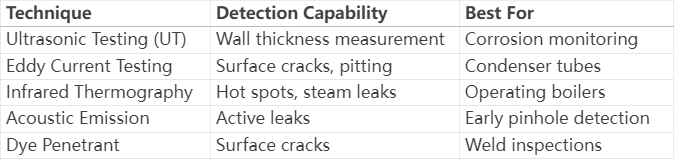

Early detection of boiler tube leaks can prevent minor issues from becoming major failures. Modern detection methods include:

· Abnormal changes in drum level

· Unexplained makeup water demand

· Sudden fluctuations in furnace draft

· Increased flue gas moisture content

· Unusual noise patterns (hissing, popping)

· Online water chemistry monitoring (pH, conductivity, oxygen)

· Distributed temperature sensing (DTS) systems

· Acoustic monitoring arrays

· Smart boiler analytics platforms

For emergency situations when immediate shutdown isn't possible:

· External clamp repairs

· Tube plugging procedures

· Epoxy-based sealants (short-term only)

· Pressure reduction strategies

· Tube welding repairs:

o TIG welding for critical sections

o Weld overlay for corrosion protection

o Post-weld heat treatment requirements

· Tube replacement guidelines:

o Sectional replacement vs. full tube replacement

o Proper expansion techniques

o Weld procedure qualifications

· Advanced repair technologies:

· o Laser cladding for erosion protection

o HVOF coatings for high-wear areas

o Composite wrap systems

· Maintaining proper pH (10.5-11.5 for drum boilers)

· Oxygen scavenger control (hydrazine alternatives)

· Phosphate treatment programs

· Blowdown optimization

· Condensate polishing

· Proper startup and shutdown procedures

· Load change rate limitations

· Avoiding low-flow conditions

· Combustion optimization to minimize slagging

· Annual internal inspections

· Tube sampling programs

· Deposit analysis and scaling prevention

· Fireside cleaning schedules

· Tube wall thickness mapping

· Upgrade to SA-213 T91/T92 alloys for high-temperature sections

· Ceramic coatings for erosion protection

· Improved tube bend designs

· Advanced weld configurations

· Cost breakdown of unplanned outages

· Comparative analysis of repair vs. replacement

· ROI calculations for prevention technologies

· Insurance and liability considerations

Preventing boiler tube leaks requires a systematic approach combining proper design, operational discipline, advanced monitoring, and proactive maintenance. By implementing the strategies outlined in this guide, operators can significantly reduce the frequency and severity of boiler tube leaks, resulting in:

· 30-50% reduction in forced outages

· 15-25% improvement in heat rate efficiency

· Substantial extension of boiler service life

· Improved safety and regulatory compliance

For facilities experiencing persistent boiler tube leaks, consulting with specialized boiler engineers and implementing a customized tube management program can provide long-term solutions tailored to specific operating conditions.