Sharing China-Made with Global Customers

When it comes to building a reliable and efficient drill string, the heavy weight drill pipe (HWDP) plays a crucial role. It serves as the transition between the regular drill pipe and the drill collar, providing both flexibility and strength. Understanding the key specifications and material grades of this essential drilling component can help operators make better purchasing and operational decisions.

A heavy weight drill pipe is a type of drill stem member designed to provide a gradual transition in stiffness between the drill collar and the drill pipe. This minimizes fatigue failures in the drill string and enhances weight distribution on the bit.

Typically, HWDP is characterized by a thick-walled center section and tool joints welded or friction-welded to both ends. It can be used in directional drilling, high-deviation wells, and deep drilling operations where additional weight and strength are required.

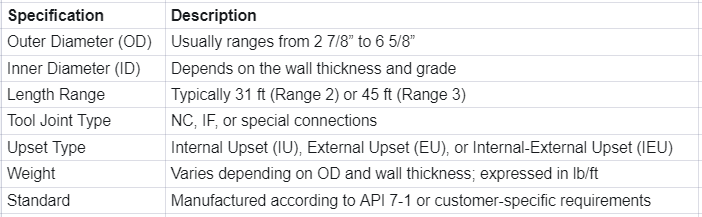

The specifications of a heavy weight drill pipe are defined primarily by API Specification 7-1, which sets the global industry standard. Key parameters include:

These parameters determine not only the mechanical performance but also compatibility with the rest of the drill string.

Different drilling environments require HWDPs with specific mechanical properties. The material grade defines the tensile strength, yield strength, and hardness of the pipe body. Common grades include:

· Grade E-75

o Yield Strength: 75,000 psi

o Suitable for shallow and medium-depth drilling

o Offers good flexibility and fatigue resistance

· Grade X-95

o Yield Strength: 95,000 psi

o Used in moderate drilling operations where higher strength is needed

· Grade G-105

o Yield Strength: 105,000 psi

o Excellent for deep wells and high-torque operations

o Provides a balance between strength and toughness

· Grade S-135

o Yield Strength: 135,000 psi

o The most common premium grade used in challenging drilling conditions

o Offers superior fatigue resistance and high tensile capacity

Choosing the right grade of heavy weight drill pipe ensures safety, longer lifespan, and optimal drilling efficiency.

High-quality HWDPs are made from alloy steel that undergoes strict heat treatment and mechanical testing. Common processes include:

· Friction Welding: Used to attach tool joints to the pipe body.

· Heat Treatment: Ensures uniform mechanical properties and toughness.

· Hardbanding: A wear-resistant overlay applied to the center section or tool joints to reduce wear in abrasive formations.

· Non-Destructive Testing (NDT): Includes ultrasonic, magnetic particle, and visual inspections to detect cracks and inclusions.

These processes guarantee reliability even under extreme downhole conditions.

When selecting HWDP for a project, consider the following:

· Drilling Depth & Formation Type – Deep wells and hard formations require higher grades like G-105 or S-135.

· Connection Compatibility – Ensure tool joints match the existing drill string.

· Bending and Fatigue Resistance – Especially critical for directional or horizontal drilling.

· API Compliance – Always verify that the product meets API 7-1 standards or equivalent.

By aligning specifications and grades with operational needs, you can optimize drilling performance while minimizing downtime and maintenance costs.

The heavy weight drill pipe is a vital link in any drilling system, balancing strength, flexibility, and durability. Understanding its key specifications and grades—along with manufacturing quality and inspection standards—helps ensure safe and efficient operations. Whether for onshore, offshore, or directional drilling, choosing the right HWDP grade can make a significant difference in performance and cost-effectiveness.

If you’re looking for a complete drilling solution that meets the highest industry standards, our API Drill Pipe is the perfect complement to your heavy weight drill pipe selection. Manufactured according to API Spec 5DP and API Spec 7-1, our drill pipes are made from premium alloy steel and undergo rigorous quality control, including full-length ultrasonic and magnetic particle inspection.

Our API Drill Pipe products offer:

· Exceptional tensile and torsional strength for demanding drilling environments

· Precision machined tool joints for reliable connection integrity

· Advanced hardbanding options to reduce wear and extend service life

· Compatibility with standard and custom HWDP connections

By combining our API Drill Pipe with high-performance heavy weight drill pipes, you can build a durable, efficient, and cost-effective drill string that performs consistently even under the toughest drilling conditions.

Contact us today to learn more about our API-certified drill pipes and how they can enhance your drilling operations.