Sharing China-Made with Global Customers

Steel pipe piles are among the most reliable and versatile foundation solutions used in marine, bridge, and deep foundation projects. Their high strength, ease of installation, and adaptability to various soil conditions make them a preferred choice in both onshore and offshore applications.

This guide provides a complete overview of steel pipe pile design, covering design principles, load capacity calculation, material selection, and engineering considerations according to major international standards.

A steel pipe pile is a tubular section driven, drilled, or jacked into the ground to support vertical and lateral loads. They can be:

· Open-ended piles, which allow soil plug formation and are common in marine works.

· Closed-ended piles, sealed with a plate or cone to increase end bearing.

· Concrete-filled piles, which combine steel and concrete to enhance stiffness and resistance.

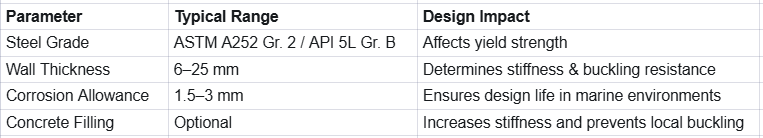

Typical diameters range from 200 mm to over 3,000 mm, and wall thickness varies from 6 mm to 40 mm depending on design load and soil conditions.

The steel pipe pile design process involves determining the geometric dimensions, material grade, and load capacity to meet structural and geotechnical requirements.

Key factors include:

· Axial load capacity (compression and tension)

· Lateral load resistance

· Buckling and slenderness ratio

· Soil–pile interaction

· Corrosion allowance and durability

3.1 Design Standards

Common standards and codes for steel pipe pile design:

· API RP 2A (for offshore structures)

· ASTM A252 / A500 (material specifications)

· AASHTO LRFD Bridge Design Specifications

· EN 1993 and EN 1997 (Eurocode for steel and geotechnical design)

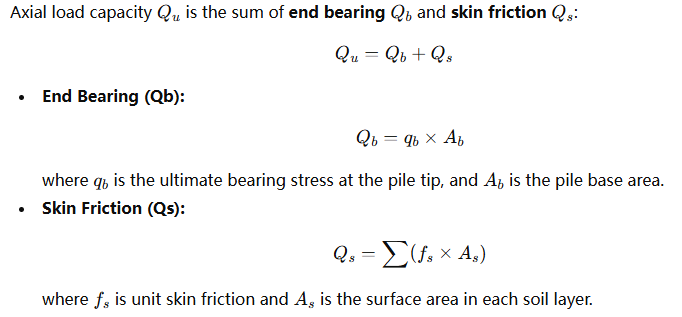

4.1 Axial Load Capacity

4.2 Lateral Load Capacity

Lateral resistance depends on pile stiffness (EI)(EI)(EI) and soil modulus (kh)(k_h)(kh).

Engineers use p–y curve methods or finite element analysis to determine lateral deflection and bending moments.

4.3 Design Example

A 600 mm diameter, 12 m long steel pipe pile embedded in medium dense sand (γ = 18 kN/m³, φ = 32°) typically achieves an ultimate axial capacity between 1,200–1,800 kN depending on soil plug formation.

Welding quality and joint configuration (butt-welded, spliced) must comply with AWS D1.1 or equivalent standards.

· Soil Type: Cohesive vs. granular soils require different friction parameters.

· Plugging Effect: Open-ended piles may form a soil plug, effectively acting as closed-ended piles.

· Negative Skin Friction: In compressible soils, downdrag forces must be considered.

· Group Effect: Interaction between adjacent piles reduces effective capacity; group efficiency factor (η) is used for adjustment.

In marine or coastal projects, steel pipe piles are exposed to harsh environments:

· Apply epoxy or polyurethane coatings

· Use cathodic protection (zinc anodes or ICCP systems)

· Allow sacrificial steel thickness for long-term corrosion loss

· Employ concrete filling for inner surface protection

Quality assurance ensures that the designed capacity is achieved in the field:

· NDT Methods: ultrasonic testing (UT), radiography (RT), magnetic particle (MT)

· Field Testing: static load tests, dynamic pile driving analysis (PDA)

· Monitoring: driving records, penetration resistance, and integrity testing (PIT)

· Always verify the pile design through both structural and geotechnical checks.

· Consider driving stresses during installation—use wave equation analysis (WEAP).

· For offshore projects, combine hydrodynamic loads and fatigue analysis in design.

· Maintain coordination between structural, geotechnical, and corrosion engineers throughout the project.

A well-executed steel pipe pile design ensures structural safety, cost-effectiveness, and long-term performance of foundations in complex environments. By understanding load mechanisms, proper design methods, and quality assurance practices, engineers can optimize foundation systems that perform reliably under demanding conditions.