Sharing China-Made with Global Customers

Selecting the wrong piping for your energy system causes safety risks and costly downtime. You need a system that lasts and performs well under pressure. I will show you how to pick the perfect tubes for your specific needs. Boiler tubes are seamless or welded metal components used to heat water or generate steam in industrial machinery. They come in two main categories: fire-tube and water-tube. Selecting the right boiler tubes depends on pressure requirements, temperature limits, and the corrosive nature of the environment.

Buying pipes is hard, but I will make it simple for you today.

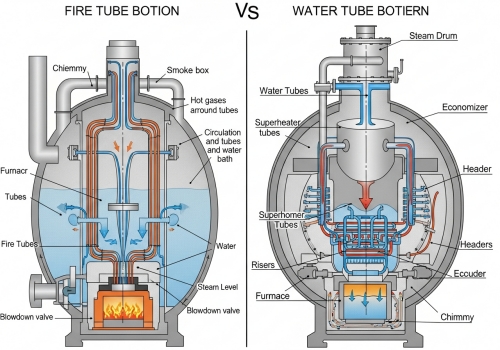

You might be confused by the different operating principles of industrial boilers. If you mix them up, your plant efficiency drops immediately. Here is the clear breakdown of how they work. The main difference lies in where the water and heat interact. In fire-tube boilers, hot gases pass through tubes surrounded by water. In water-tube boilers, water flows inside the tubes while hot gases surround them. Water-tube designs generally handle higher pressures and temperatures better than fire-tube designs.

I have worked with many clients in the EPC sector, and understanding the core mechanics is the first step to saving costs. Let's look deeper at the Fire Tube boiler first. In this system, the heat source is inside the tube. The water sits in a large tank around these hot pipes. This turns the water into steam. This design is very simple. It is easy to maintain. However, it has limits. It is usually good for low to medium pressure applications, usually under 350 PSI. On the other hand, we have the Water Tube boiler. Here, the water flows inside the boiler tubes. The fire burns outside the tubes. This allows for much higher pressure. We see these used in large power plants where pressure exceeds 3,000 PSI. The surface area for heating is larger, so the boiler responds faster to changes in load. While the Fire Tube is cheaper upfront, the Water Tube is more efficient for heavy-duty work. At Centerway Steel, we supply components for both systems, but we always ask about your pressure needs first.

| Feature | Fire Tube Boiler | Water Tube Boiler |

|---|---|---|

| Water Location | Outside the tubes | Inside the tubes |

| Heat Location | Inside the tubes | Outside the tubes |

| Pressure Limit | Low to Medium (up to 350 PSI) | High (up to 3,000+ PSI) |

| Application | Heating, Small Factories | Power Plants, Large Industry |

| Efficiency | Lower | Higher |

Material failure leads to leaks and dangerous explosions in your plant. You cannot afford weak metal when lives are at risk. Let us look at the chemical properties that keep your project safe. Carbon steel is cost-effective for low-to-medium pressure. However, for high-pressure and corrosive environments, stainless steel or alloy steel boiler tubes are necessary because they offer superior strength and heat resistance.

When I help purchasing managers select materials, I always start with the environment. If your project is inland and uses clean water, Carbon Steel is a great choice. It is made of iron and carbon. It is strong enough for standard boilers. It is also cheaper to manufacture. Standards like ASTM A179 or A192 are very common here. This helps you save money on the project budget. However, if you are building a power plant near the coast, or using aggressive chemicals, Carbon Steel will rust. It cannot handle the corrosion. This is where Stainless Steel or Alloy Steel comes in. These materials contain nickel and chromium. This mixture creates a shield against rust. It also handles extreme heat much better than simple carbon steel. Although the price is higher, the lifespan is much longer. You do not want to replace pipes every two years. We also see Alloy Steel used often in high-heat areas. For example, ASTM A213 T11 or T22 grades are very popular for superheaters. They bridge the gap between standard carbon steel and expensive stainless steel.

| Material Type | Common Standards | Key Advantage | Typical Use |

|---|---|---|---|

| Carbon Steel | ASTM A179, A192, A210 | Low Cost, Easy to Weld | Low/Medium Pressure Boilers |

| Alloy Steel | ASTM A213 T11, T22, T91 | High Heat Resistance | Superheaters, Heat Exchangers |

| Stainless Steel | ASTM A213 TP304, TP316 | Corrosion Resistance | Chemical Plants, Coastal Areas |

Managing multiple vendors is a massive headache for purchasing managers and slows down construction. Delays kill project timelines and increase your stress. You need a partner who does it all from start to finish. A reliable supplier offers integrated services, including production, testing, and logistics. Look for ISO certifications and a history of serving major global clients like CNPC or Shell to ensure you get high-quality boiler tubes.

In my experience at Centerway Steel, I see the struggles of EPC companies. You have tight deadlines. You cannot wait for one supplier to make the pipe and another to coat it. You need a one-stop solution. This is our mission. We integrate production, inventory, and sales. We have been doing this since 1996. When you look for a supplier, you must check their testing capabilities. Do they do Eddy Current testing? Do they perform Hydrostatic tests? These tests ensure the pipe will not burst. We have certifications like ISO 9001 and ISO 45001. Our products are inspected by SGS and TUV. This gives you peace of mind. Furthermore, a good supplier understands global logistics. We have partners in over 100 countries. Whether you are in the Middle East or Southeast Asia, we know how to ship large diameter or ultra-long pipes. We have served giants like Petronas and ExxonMobil. We bring that same level of professional service to every client. We treat your project as our own. We want a win-win cooperation.

| Service Aspect | Why It Matters | Centerway Steel Capability |

|---|---|---|

| Quality Control | Prevents failure | ISO Certified, Third-party inspection (SGS/BV) |

| Range of Product | One purchase order | Pipes, Fittings, Valves, Coatings |

| Global Logistics | On-time delivery | Export experience to 100+ countries |

| Track Record | Proven reliability | Supplier for Fortune 500 EPC companies |

To build a safe boiler, you must choose between fire-tube and water-tube designs, select the right carbon or stainless material, and partner with a certified supplier like Centerway Steel.