Sharing China-Made with Global Customers

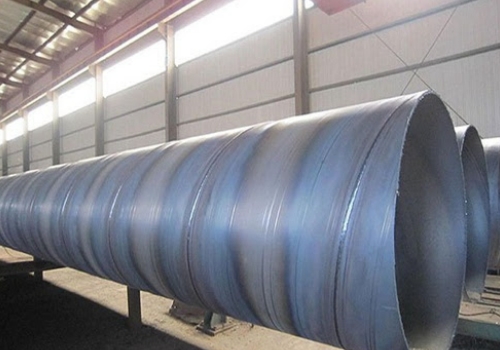

You face pressure to find durable pipes for large construction projects. Sourcing the wrong material causes delays and budget issues. I will explain why SSAW pipes are your best cost-saving solution. SSAW steel pipe stands for Spiral Submerged Arc Welded pipe. Manufacturers make it by rolling steel coils into a spiral shape and welding them inside and out. It offers high strength and large diameters at a low cost, making it perfect for water transport, piling, and construction.

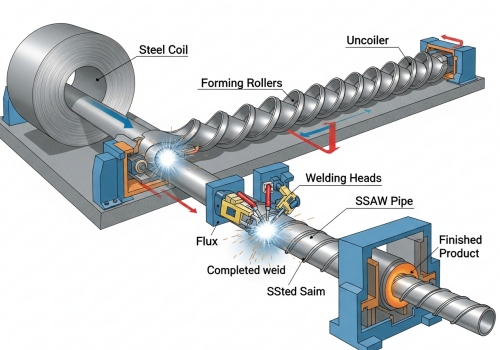

Many buyers get confused by the different types of welded pipes available today. You might wonder how we create such large pipes from a simple roll of steel. I will break down the manufacturing process for you. This helps you understand the quality behind the product.

You worry about pipe defects ruining your project timeline. Bad welds often cause leaks or structural failures. We use a specific, controlled process to stop this from happening. The manufacturing process starts with hot-rolled steel coils. The machine uncoils the steel strip and rolls it into a spiral shape. We use double-sided submerged arc welding technology. This creates a strong weld seam that runs spirally along the pipe body, allowing us to produce very large diameters from standard-width coils.

I want to take you deeper into this process because it affects the final quality. The raw material is a steel coil. We uncoil this strip and level it. The most interesting part is the forming angle. We can change the angle of the steel strip entering the forming machine. This means I can use the same width of steel strip to make pipes of many different diameters. This is very different from other methods that need a specific width for every size. The welding happens both inside and outside. We call this double-sided submerged arc welding. This technique ensures full penetration and a very strong bond. After welding, we cut the pipe to the required length. It is a continuous process. This allows us to make pipes much longer than the standard 12 meters. We can produce lengths up to 35 meters or more if your transport allows it. At Centerway Steel, we do not stop there. Every ssaw steel pipe undergoes strict testing. We use ultrasonic testing and X-rays on the welds. We also perform hydrostatic tests where we fill the pipe with water under pressure. This proves the pipe can handle the workload. We inspect the appearance and measure the dimensions. We do this from the moment the raw coil arrives until we put the finished pipe in our warehouse. This ensures you get exactly what you ordered.

Projects always have tight budgets and strict requirements. You cannot afford to waste money on the wrong materials. You need to know the risks and benefits before you buy. SSAW steel pipe offers great price advantages and production flexibility. We can make huge diameters up to 3500mm easily. However, it is not ideal for very high-pressure applications compared to seamless pipes. It is best suited for structural piles, water transmission, and low-pressure fluid transport.

Let us look at why you might choose this pipe. The biggest benefit is the cost. The raw material is steel coil, which is cheaper than the steel plates used for LSAW pipes. The production efficiency is very high. This lowers your purchasing cost significantly. For a large project, this saves a lot of money. Also, we can make very large diameters. We can produce sizes from 219mm all the way up to 3500mm. Other processes hit a limit much sooner. But you must be aware of the limitations. The spiral weld is longer than a straight seam weld. This means there is more "heat-affected zone" on the pipe. For extremely high-pressure oil and gas lines, some engineers prefer LSAW or Seamless pipes. Also, the dimensional accuracy of the roundness is sometimes slightly less than LSAW pipes, though modern machines have improved this greatly. Here is a simple table to help you compare:

| Feature | SSAW Steel Pipe | LSAW Steel Pipe | Seamless Pipe |

|---|---|---|---|

| Raw Material | Steel Coil (Cheaper) | Steel Plate (Expensive) | Round Billet |

| Diameter Range | Large (up to 3500mm) | Medium to Large | Small to Medium |

| Production Cost | Low | High | High |

| Weld Seam | Spiral | Straight (Longitudinal) | None |

| Main Use | Piling, Water, Low Pressure Gas | High Pressure Oil & Gas | High Pressure / Critical |

For structural uses like piling in port construction or bridges, the ssaw steel pipe is the champion. The spiral seam actually stops cracks from spreading straight through the pipe. This adds safety to the structure.

Wrong specifications can ruin an entire engineering project. Standards are often confusing and vary by country. We clarify exactly what you need to look for to ensure compliance. Common standards include API 5L for oil and gas pipelines and ASTM A252 for piling. Dimensions vary greatly, with diameters from 219mm to over 3000mm. Wall thickness ranges from 5mm to 25mm depending on the project requirements. We also supply pipes meeting European standards like EN 10217 and EN 10219. When you source pipes, you must match the standard to the application. If you are building a foundation for a building or a bridge, you likely need ASTM A252. This is the standard for welded and seamless steel pipe piles. It focuses on the physical strength of the steel. If you are transporting water or oil, you need API 5L or ASTM A53. These standards focus on the pressure capabilities and the chemical composition of the steel. For our customers in Europe, we often work with EN 10219 for structural uses and EN 10217 for pressure purposes. We supply ssaw steel pipe in various steel grades. Common grades include Grade B, X42, X52, X60, and X70. Higher numbers mean stronger steel. We also provide different coatings to protect the pipe from rust. You can choose 3LPE (3-layer polyethylene), FBE (Fusion Bonded Epoxy), or simple painting. Here is a breakdown of the typical supply range at Centerway Steel:

· Wall Thickness: 5 mm – 25 mm

· Length: 6m, 12m, up to 35m

· Coatings: Galvanized, 3LPE, FBE, Cement Lined We have inspected our products with SGS, BV, and TUV. This means you do not have to worry about quality. We have served customers in over 100 countries. We understand that getting the right standard prevents problems during installation.

SSAW steel pipe is a strong, cost-effective choice for large-diameter projects like piling and water transport. We ensure quality through rigorous testing. Centerway Steel is your reliable partner for global pipeline solutions.