Sharing China-Made with Global Customers

You need pipes for high-pressure projects, but standard options often fail under stress. This risks safety and costs your company money. We offer the perfect solution with our robust steel pipe technology. A longitudinal submerged arc welding pipe is produced by bending steel plates into a cylinder and welding the seam using a double-sided submerged arc process. This method creates pipes with thick walls and large diameters, making them ideal for high-pressure oil, gas, and construction applications.

I know how hard it is to choose the right pipe for critical projects. You have to balance cost, quality, and delivery time. I have been in this industry for many years. I see many buyers struggle with these decisions. Let me walk you through the details of this specific pipe type. This will help you make the best decision for your next project.

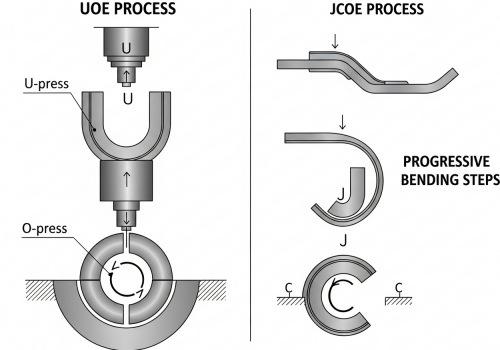

Choosing the wrong manufacturing method leads to poor fit-up and delays. You waste valuable time on site trying to fix these issues. We help you understand the specific forming processes to avoid these problems. UOE and JCOE are the two main forming methods. UOE shapes the plate in a U then O shape for high-volume production. JCOE bends the plate progressively, offering more flexibility for custom sizes. Both result in high-quality longitudinal submerged arc welding pipes.

I want to explain the production process in detail. This helps you understand why these pipes are so strong. The process starts with a steel plate. We call this the raw material. The most common methods to shape this plate are UOE and JCOE. In the UOE method, we press the plate into a "U" shape first. Then we press it into an "O" shape. This method is very fast. It is good for large orders with the same size. However, it requires expensive molds. The JCOE method is different. We bend the plate many times. We bend the edge first. Then we press it into a "J" shape. Next is the "C" shape. Finally, it becomes an "O" shape. This process is slower than UOE. But it is very flexible. We can make many different sizes without changing expensive molds. After forming, we weld the seam. We use double-sided submerged arc welding. This means we weld from the inside and the outside. This makes the weld very strong. Finally, we do a mechanical expansion. This step is crucial. It ensures the pipe is perfectly round. It also relieves stress in the steel. Here is a simple comparison for you:

| Feature | UOE Method | JCOE Method |

|---|---|---|

| Production Speed | Very Fast | Moderate |

| Flexibility | Low (Fixed sizes) | High (Custom sizes) |

| Mold Cost | High | Low |

| Main Use | Mass production | diverse specifications |

At Centerway Steel, we use these processes to meet your specific needs. We ensure the longitudinal submerged arc welding pipe fits your project perfectly.

Pipeline failures cause environmental disasters and massive financial loss for your company. You cannot afford to use weak materials in critical areas. Our pipes provide the strength and durability required for extreme conditions. LSAW pipes offer superior wall thickness and diameter options compared to ERW pipes. They resist high internal pressure and low-temperature corrosion. This makes them the top choice for oil and gas transmission, offshore platforms, and structural piling in difficult environments.

I have seen many projects in the oil and gas industry. The demands are very high. You need pipes that can handle high pressure. You also need pipes that resist corrosion. This is where the longitudinal submerged arc welding pipe excels. Standard pipes like ERW (Electric Resistance Welding) are good for small sizes. But they cannot handle thick walls. Seamless pipes are great but very expensive for large diameters. LSAW pipes fill this gap. They cover a diameter range from 16 inches up to 60 inches. They can also have very thick walls. This is vital for high-pressure lines. We supply these pipes to many industries. The most common use is oil and natural gas transportation. The pipes must travel long distances. They go through mountains and under the sea. The LSAW pipe is strong enough for this. Another big application is construction. We see these pipes used for piling. They support bridges and buildings. They are also used in water treatment plants and central heating systems. Our clients include big names like CNPC and Shell. They choose LSAW because it is reliable. It is also cost-effective for large projects. You get the strength of a seamless pipe with the economy of a welded pipe. Below is a breakdown of where we see these pipes used most often:

· Construction: Piling for bridges, ports, and skyscrapers.

· Water Systems: Large diameter sewage and water supply mains.

· Energy: Penstocks for hydroelectric power stations.

Hidden defects in steel pipes lead to leaks and ruptures after installation. This destroys your project's timeline and reputation. We implement rigorous testing to catch every imperfection before the pipe leaves our factory. Quality control involves destructive and non-destructive testing. We use ultrasonic and X-ray inspection to check the weld seam. We also perform hydrostatic testing and mechanical tests like tensile strength and impact toughness to guarantee the pipe meets international standards.

Quality is the most important part of my job. I know you cannot accept a bad pipe. A failure on site is a disaster. That is why we have a strict inspection process. We follow international standards like API 5L. First, we check the chemistry. We analyze the steel plate. We make sure it has the right elements. This ensures the steel is strong and weldable. Then we focus on the weld. The weld is the most critical part. We use X-ray examination. This lets us see inside the weld. We look for cracks or air pockets. We also use ultrasonic testing. This uses sound waves to find defects. These are Non-Destructive Tests (NDT). They do not damage the pipe. We also do mechanical testing. We take a sample of the pipe. We pull it until it breaks. This is the tensile strength test. We also bend it and hit it. This checks for toughness. Every pipe undergoes a hydrostatic test. We fill the pipe with water. We pressurize it to a level higher than the working pressure. We hold it there. This proves the pipe will not leak. We also check the dimensions. We measure the diameter, wall thickness, and length. We check the ovality. The pipe must be perfectly round. Here is a summary of our testing steps:

1. Chemical Analysis: Checks raw material composition.

2. Visual Inspection: Checks for surface defects.

3. Hydrostatic Test: Verifies pressure handling.

4. Ultrasonic & X-Ray: Detects internal weld flaws.

5. Mechanical Testing: Confirms strength and ductility. At Centerway Steel, we provide all these test reports. You get a full data package with your longitudinal submerged arc welding pipe.

The longitudinal submerged arc welding pipe is the best choice for high-pressure and large-diameter projects. Centerway Steel provides high-quality, fully tested LSAW pipes to ensure your project's safety and success.