Vision/Value: Pragmatism, Integrity, Passion

Are you struggling to decide between LSAW and SSAW pipes for your next pipeline project? Making the wrong choice can lead to safety risks, project delays, and wasted budget. LSAW steel pipe features a longitudinal weld ideal for high-pressure environments, while SSAW uses a spiral weld suited for low-pressure, cost-effective applications. Your selection depends entirely on the specific pressure ratings, project location, and safety classes required by your engineering team.

Many purchasing managers I speak with assume these pipes are interchangeable because they both use submerged arc welding, but the structural differences are massive. Let's break down the technical specifics so you can procure the exact materials your engineers need without overspending.

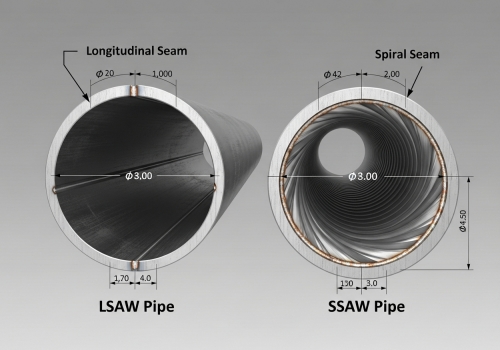

Confused by the technical jargon of JCOE versus Helical welding in supplier quotes? It is vital to understand how these pipes are formed to predict their long-term behavior. LSAW steel pipe is manufactured from steel plates using the JCOE process to form a single straight seam. In contrast, SSAW is made from steel coils rolled into a spiral helix. This fundamental difference in raw material dictates their mechanical consistency.

When I walk through our Centerway Steel production floor, the difference in manufacturing becomes obvious. LSAW (Longitudinal Submerged Arc Welding) pipes start as single flat steel plates. We use a heavy-duty molding machine to press the plate into a "J" shape, then a "C" shape, and finally an "O" shape (hence the name JCOE) before welding the seam. This process is slower but produces a pipe with incredible dimensional accuracy and uniform wall thickness. Because we use steel plates, the material properties are usually isotropic, meaning they have the same strength in all directions. On the other hand, SSAW (Spiral Submerged Arc Welding) uses hot rolled steel coils. The coil is unspooled and turned into a spiral, like the cardboard inside a roll of paper towels. While this allows us to make very large diameter pipes from narrow strips of steel, it introduces physical variables. Steel plates used for LSAW are generally produced with higher quality control than the coils used for SSAW. If your project demands strict tolerance on wall thickness and out-of-roundness, the plate-based manufacturing of LSAW is usually the superior choice. At Centerway Steel, we have seen that for diameters between 16 inches and 60 inches, LSAW offers the most consistent geometry for welding in the field.

| Feature | LSAW Pipe | SSAW Pipe |

|---|---|---|

| Raw Material | Steel Plate | Steel Coil |

| Forming Method | Cold forming (JCOE or UOE) | Spiral rolling |

| Weld Orientation | Longitudinal (Straight) | Helical (Spiral) |

| Diameter Range | 16" - 60" (406mm - 1500mm) | 20" - 100" (508mm - 2540mm) |

Are you worried about potential pipeline failure in high-pressure environments? The weld seam is usually the weakest link in any piping system, so its orientation matters. Yes, generally speaking. The straight seam of an LSAW steel pipe is significantly shorter and endures less residual stress than the longer spiral seam of SSAW pipes, making LSAW superior for high-pressure and critical applications.

From an engineering perspective, the performance difference comes down to physics and probability. The weld seam on an SSAW pipe is much longer than that of an LSAW pipe—sometimes by a factor of two or three depending on the helix angle. Mathematically, a longer weld means a higher probability of defects like air holes, cracks, or inclusions. I always explain to my clients that if you have more seam, you have more potential points of failure. This is why strict testing is required. Furthermore, when a pipe is under internal pressure, the main stress is on the hoop direction (perpendicular to the pipe axis). In an LSAW pipe, the weld faces this stress directly, but because the weld is short and the heat-affected zone is minimized, we can control the quality very tightly. In SSAW pipes, the residual stress from the spiral forming process can be significant. While modern SSAW technology has improved, for Class 1 and Class 2 areas (like cities or offshore platforms) defined by API standards, the lower defect risk of LSAW makes it the safer bet. At Centerway Steel, we recommend LSAW for any project where the consequence of failure is high, such as projects we have supplied for CNPC or Shell.

| Performance Metric | LSAW Pipe | SSAW Pipe |

|---|---|---|

| Weld Length | Short (100% of pipe length) | Long (Relative to helix angle) |

| Residual Stress | Low | Medium to High |

| Pressure Resistance | Excellent (High Pressure) | Good (Medium/Low Pressure) |

| Common Defects | Rare | More likely due to weld length |

Are you under pressure to reduce total project costs without compromising safety? Knowing exactly where to apply each pipe type is the secret to smart procurement. Use SSAW for piling, water transport, or Class 3/4 areas to save money. Choose LSAW steel pipe for oil and gas trunk lines and urban areas where regulatory safety standards are non-negotiable.

I have seen many Purchasing Managers make the mistake of looking only at the price per ton. Yes, SSAW pipe is generally cheaper because steel coil costs less than steel plate, and the production efficiency is higher. If you are buying for a water treatment plant, a sewage line, or structural piling for a bridge, SSAW is the perfect, cost-effective solution. It does the job well without breaking the bank. In fact, for very large diameters above 60 inches, SSAW is often the only practical choice because producing LSAW plates that wide is incredibly difficult and expensive. However, if your project involves high-pressure oil or gas transmission, trying to save money with SSAW can cost you more in the long run. Many international oil companies (like the Fortune 500 clients we serve) strictly mandate LSAW for main transmission lines to ensure longevity and safety. If you use SSAW in a restricted application, you risk failing inspection or facing expensive replacements later. The welding quality of LSAW pipes allows for easier on-site welding and coating, which also saves construction time. As a one-stop supplier, Centerway Steel helps you mix and match—supplying LSAW for your critical lines and SSAW for your structural needs to optimize your total budget.

| Application Scenario | Recommended Pipe | Reason |

|---|---|---|

| Offshore Oil & Gas | LSAW | High pressure, harsh environment |

| Urban Gas Mains | LSAW | Safety regulations (Class 1/2) |

| Water/Sewage | SSAW | Low pressure, cost priority |

| Structural Piling | SSAW | Large diameter needed, lower cost |

To summarize, choose LSAW steel pipe for high-pressure, critical safety projects, and select SSAW for cost-effective, large-diameter structural or water applications. Centerway Steel supplies both to meet your exact needs.