Vision/Value: Pragmatism, Integrity, Passion

Weak soil and heavy structural loads can cause nightmares for engineers and project managers. You need a foundation solution that guarantees stability and longevity without blowing your budget. A steel pipe pile is a deep foundation element used to transfer structural loads to stronger soil layers deep underground. Available in open-ended or closed-ended forms, they rely on skin friction and point bearing to support massive structures like bridges, ports, and skyscrapers.

Many purchasing managers struggle to find the right specifications for their specific soil conditions. I will explain exactly how these piles work and how to choose them.

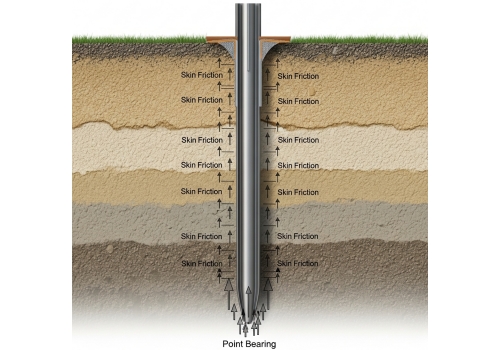

You might wonder if a hollow tube can really hold up a bridge. Understanding the mechanics of load transfer is key to trusting this material for your project. These piles work through two main forces: friction between the pile surface and the soil, and point bearing at the tip. They can be driven empty or filled with concrete to increase strength, utilizing manufacturing methods like SSAW or LSAW depending on needs.

I have seen many projects in the construction industry succeed because they understood the mechanics of the steel pipe pile. It is not just a tube. It is a sophisticated engineering tool. The pile transfers the weight of the building to the ground in two ways. First, there is skin friction. This is the resistance between the outer surface of the steel pipe and the soil surrounding it. As the pile goes deeper, this friction increases. Second, there is point bearing. This is the support provided by the firm layer of soil or rock at the very bottom of the pile. You can use these piles in two configurations.

1. Open-Ended Piles: The bottom is open. Soil enters the pipe as you drive it down. We call this a "plug." It is good for driving through hard soil layers.

2. Closed-Ended Piles: We weld a steel plate or a conical point to the bottom. This displaces the soil and creates more friction. You can fill these with concrete later. At Centerway Steel, we often recommend SSAW (Spiral Submerged Arc Welding) pipes for piling. They are strong and cost-effective. Below is a breakdown of the types we encounter most:

| Feature | Open-Ended Pile | Closed-Ended Pile | Concrete Filled Pipe |

|---|---|---|---|

| Primary Use | Offshore, Marine, Hard Soil | Land foundations, Soft Soil | Heavy duty high-rise |

| Soil Behavior | Soil enters pipe (plugging) | Soil is pushed aside | Soil pushed aside |

| Load Capacity | Relies mostly on friction | Friction + Point Bearing | Maximum capacity |

| Cost | Lower (less steel/welding) | Medium (needs plate/tip) | Higher (adds concrete) |

We ensure our pipes meet standards like ASTM A252. This is crucial for safety. The choice depends on your specific soil report.

Choosing the wrong foundation method wastes time and money. You need to know exactly where this specific steel product performs best compared to concrete alone. Steel pipe piles offer high load-bearing capacity, customization ease, and durability in harsh environments like marine ports. They are ideal for projects requiring deep penetration through soft soil to bedrock, such as wharves, oil terminals, and high-rise buildings.

In my 18 years of experience, I have seen steel pipe pile usage save projects that were behind schedule. Concrete piles are heavy and can crack during transport. Steel is different. It is tough. It handles rough handling well. The biggest advantage is customization. We can make piles in very specific diameters and thicknesses. If you need a pile that is 50 meters long, we can splice sections together onsite. You can drive them deep until you hit solid rock. This is vital for marine construction. Bridges and docks need foundations that go through water and soft mud. Steel resists the high pressure of driving better than other materials. Here is a detailed look at where our customers use them:

· Marine Structures: Docks, piers, and breakwaters. The steel can be coated to stop rust.

· Urban Buildings: Skyscrapers need deep support. Steel piles create minimal vibration compared to other methods.

· Energy Sector: Oil platforms and wind turbine towers. We supply many EPC companies in this field.

· Transport: Highway bridges and railway lines. These bear heavy, moving loads. Benefits Breakdown:

1. Load Adaptation: We can change the pipe size to fit the load.

2. Testing: You can inspect the pipe before driving. You know it is perfect.

3. Driving Ease: They cut through soil easily. This speeds up the timeline.

4. Cost Control: Larger, thicker pipes often cost less than many small concrete piles. We have supplied these for port projects in Southeast Asia and the Middle East. The feedback is always about the speed of installation. Time is money in construction.

Sourcing the wrong diameter or wall thickness shuts down production. You must ensure your supplier meets international standards like API 5L or ASTM A252. Common sizes range from 8 inches to over 50 inches in diameter. The choice depends on load requirements, soil analysis, and engineering design. Always verify steel grades and wall thickness to ensure the pile withstands driving forces without buckling.

When I talk to engineers, the conversation always turns to specs. You cannot just buy any pipe. The steel pipe pile must match the design perfectly. The most common standard we use is ASTM A252. This is the standard specification for Welded and Seamless Steel Pipe Piles. It has three grades:

· Grade 1: Lower strength, rarely used now.

· Grade 2: Very common. Good yield strength.

· Grade 3: High strength. We sell this the most for heavy projects. You also need to look at the diameter and wall thickness. We call this the "schedule." A larger diameter gives more surface area for friction. A thicker wall stops the pipe from buckling when you hit it with a hammer. Common Size Ranges we supply:

· Small: 8 inches to 12 inches. Good for light structures or underpinning.

· Medium: 12 inches to 24 inches. The standard for most buildings.

· Large: 24 inches to 50+ inches. Used in ports and major bridges. Here is a reference table for purchasing:

| Diameter (Inches) | Typical Wall Thickness | Common Application |

|---|---|---|

| 8" - 12" | 0.250" - 0.375" | Residential / Light Commercial |

| 14" - 24" | 0.375" - 0.625" | Highway Bridges / Buildings |

| 30" - 60" | 0.500" - 1.000"+ | Marine Dolphins / Deep Ports |

At Centerway Steel, we act as a one-stop shop. We produce the pipe. We cut it to length. We can apply anti-corrosion coatings. We can also weld on the driving shoes or plates. This saves you from hiring three different companies. We check every pipe with third-party inspectors like SGS or BV. This guarantees quality for your project.

Steel pipe piles provide essential support for heavy infrastructure through friction and point bearing. Choosing a reliable supplier like Centerway Steel ensures quality, customization, and project safety for your deep foundation needs.