Vision/Value: Pragmatism, Integrity, Passion

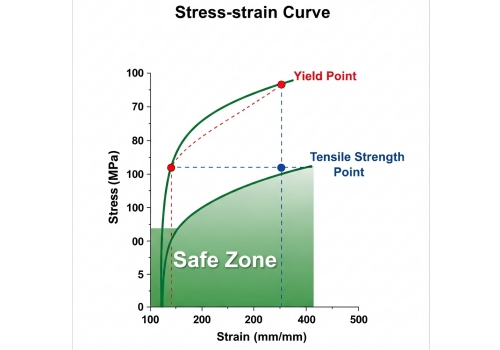

Do you worry about pipe failures destroying your project budget and timeline? Selecting the wrong material specifications can lead to catastrophic leaks or expensive over-engineering. I am here to simplify the ASME rules for you. The allowable stress for carbon steel pipe is determined by ASME B31.3 standards. For temperatures below the creep range, it is usually the lower value of 1/3 of the tensile strength or 2/3 of the yield strength. This calculation ensures your piping system remains safe under operational pressure.

Understanding these numbers is vital for safety. If you ignore them, the pipe might burst. If you blindly follow them without understanding, you might buy expensive pipes you do not need. Let us look at the details.

Reading engineering codes often feels like reading a different language. It is dense and hard to follow. But you need to understand Section 302.3.2 (d) to buy the right pipes. ASME B31.3 sets the design limits. For standard metals, the code compares tensile strength and yield strength. The allowable stress is the lowest resulting value. This ensures a safety margin before the metal permanently deforms or breaks.

I want to explain the logic behind these rules. The code splits the requirements into two main categories based on temperature. We have the "elastic range" and the "creep range." For normal temperatures (below the creep range), we look at two main numbers. First, we take 1/3 of the tensile strength (ST). Second, we take 2/3 of the yield strength (SY). We compare them. The lower number wins. This is the allowable stress. There is a special rule for austenitic stainless steel and nickel alloys. For these materials, we can sometimes go up to 90% of the yield strength. But for carbon steel, we stick to the stricter 2/3 rule. When temperatures get very high, we enter the "creep range." Creep means the metal slowly stretches over time under heat and pressure. Here, the rules change. We look at how much stress causes a 0.01% stretch in 1,000 hours. Or, we look at the stress that causes a rupture after 100,000 hours. We take percentages of these numbers (67% or 80%). The goal is to predict long-term safety. At Centerway Steel, we ensure our pipes meet these strict criteria before we ship them to your site.

You might see the formula, but how does it work for a real product? Many buyers struggle to apply the math to the actual ASTM certificates they receive. Let us look at a specific example using ASTM A106 Grade B. This is a common seamless pipe. We calculate 1/3 of its tensile strength (60ksi) and 2/3 of its yield strength (35ksi) to find the safe limit.

I will walk you through the calculation. This helps when you are checking the allowable stress for carbon steel pipe on your next project. First, look at the material properties in Table A-1 of the code. For ASTM A106 Grade B, the minimum tensile strength (ST) is 60ksi. The minimum yield strength (SY) is 35ksi. Now, we do the math:

1. Take 1/3 of the tensile strength: 60 divided by 3 equals 20ksi.

2. Take 2/3 of the yield strength: 35 multiplied by 0.66 equals 23.3ksi. Rule 1 gives us 20ksi. Rule 2 gives us 23.3ksi. The rule says we must choose the lower value. So, the allowable stress is 20ksi. This result tells us something interesting about safety factors. Since the limit is based on tensile strength (20ksi is 1/3 of 60ksi), we effectively have a safety factor of 3. This is very conservative. Let us compare this to Stainless Steel (ASTM A312 TP316).

· Tensile (ST): 75ksi.

· Yield (SY): 30ksi.

· Limit: Lower of (2/3 * 30 = 20ksi) or (90% * 30 = 27ksi).

· Result: 20ksi. Here is a table to make it clear:

| Material | Tensile Strength (ST) | Yield Strength (SY) | Calculated 1/3 ST | Calculated 2/3 SY | Allowable Stress |

|---|---|---|---|---|---|

| Carbon Steel (A106 GrB) | 60 ksi | 35 ksi | 20 ksi | 23.3 ksi | 20 ksi |

| Stainless Steel (TP316) | 75 ksi | 30 ksi | 25 ksi | 20 ksi | 20 ksi |

Pipes rarely stay at room temperature in an industrial plant. Does the allowable stress for carbon steel pipe stay the same when things get hot? No, stress limits drop as heat rises. For carbon steel, the allowable stress stays steady up to 400°F. Above that, it drops sharply. Once you pass 700°F, creep becomes the main factor, and the material gets much weaker.

Temperature is the enemy of steel strength. When I supply pipes for refineries, I always ask about the operating temperature. This is why. For ASTM A106 Grade B, the allowable stress holds at 20ksi from room temperature up to 400°F. This is the "safe zone." Between 400°F and 700°F, the rules shift. The yield strength at that specific temperature becomes important. You will see the allowable stress value decrease. It is governed by 2/3 of the yield strength at that heat. Once you go above 700°F, the allowable stress for carbon steel pipe falls off a cliff. This is where the "creep properties" take over. The slope on the chart gets very steep. The metal is not just bending; it is slowly deforming over time. Compare this to Nickel Alloy (UNS N06625). It stays strong up to much higher temperatures. Its curve is flatter. But for Carbon Steel, you must be very careful above 700°F. If your project operates at these high heats, you might need a different material. Centerway Steel can help you switch from Carbon Steel to Alloy Steel if the stress limits get too low. We want to make sure your design is safe for the long haul.

Calculating the allowable stress for carbon steel pipe protects your project. You must use the lower value of 1/3 tensile or 2/3 yield strength. Watch out for high temperatures. Centerway Steel is ready to supply the right safe materials for you.