Vision/Value: Pragmatism, Integrity, Passion

Selecting the right boiler for your industrial project is often confusing and stressful. If you make the wrong choice, you might face high operating costs or a system that cannot handle your steam load. I will help you understand the specific differences so you can make the right buying decision. The main choice in a fire tube vs water tube boiler comparison comes down to pressure and load type. A fire tube boiler has hot gases inside tubes surrounded by water and is best for steady, low-pressure needs. A water tube boiler has water inside tubes surrounded by fire and is superior for high-pressure, variable loads.

Many people stop reading here because they think they know the answer. But the details of the internal design will tell you exactly what kind of maintenance you will face later. You need to see how the steel tubes operate inside the shell.

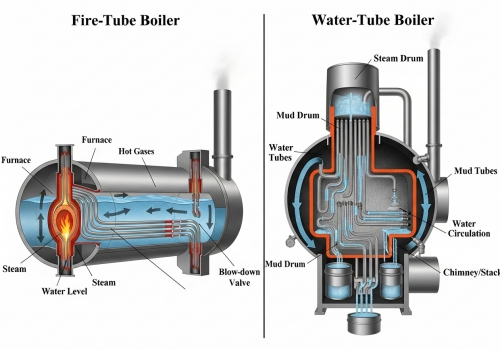

It is difficult to visualize how these massive machines work when you only see the metal shell from the outside. You need to understand the internal flow to know which one fits your factory layout. The core structural difference helps you understand the fire tube vs water tube boiler debate. In a fire tube design, the flame goes through the tubes. In a water tube design, the water goes through the tubes. This simple inversion changes everything about the size and pressure limits.

I have been in this industry since 1996, and I have seen the insides of thousands of boilers. When we supply steel pipes to manufacturers, the design dictates the pipe specifications. Let’s break down the fire tube boiler first. It is essentially a tank of water. We call the tubes "passes." The heat travels back and forth through these tubes three or four times. We call this a 3-pass or 4-pass system. Because the whole tank is full of water, it is very heavy. But this large volume of water acts like a thermal battery. On the other hand, the water tube boiler is the opposite. The water flows through smaller tubes, and the fire is on the outside. This means there is much less water in the system at any one time. The design allows for very fast circulation. Because the water is contained in small-diameter pipes rather than a large tank, the engineering physics changes. Small tubes can handle much higher internal pressure than a large shell. This is why water tube boilers are the standard for heavy industrial power generation where pressures are very high. As a supplier, I know that the steel grade requirements for water tube boilers are often stricter because they face higher temperatures and pressures.

Every construction project has different demands for steam and hot water. If you ignore your specific load profile, you might buy a system that fails when you need it most. Comparing the performance of a fire tube vs water tube boiler reveals distinct strengths. Water tube boilers can reach pressures up to 5000 psig and handle load swings easily. Fire tube boilers are limited to roughly 350 psig but are easier to maintain and offer a large steam reserve for sudden, short bursts.

We need to look deeper into the operational costs and risks. This is where my experience with EPC companies helps. I often talk to engineers who regret their choice because of maintenance issues. Fire tube boilers are generally cheaper to operate. They have a simple design. You can easily open the doors and clean the tubes. If a tube breaks, it is not a disaster to replace it. Also, because they hold 4 to 8 times more water than water tube boilers, they are forgiving. If your water quality is not perfect, the large volume dilutes the dirt and scale. However, water tube boilers are speed demons. They hold very little water, so they can start up from cold very quickly. A fire tube boiler is like heating a swimming pool; it takes hours. A water tube boiler is ready in minutes. This makes the water tube design perfect for varying loads. If your factory needs a lot of steam suddenly, the water tube boiler responds fast. The downside is that they are sensitive. Because the water volume is small, you must treat the water carefully. If scale builds up in the tubes, they can overheat and fail rapidly. Below is a simple comparison table to help you visualize the trade-offs:

| Feature | Fire Tube Boiler | Water Tube Boiler |

|---|---|---|

| Pressure Limit | Low (Usually < 350 psig) | High (Up to 5000 psig) |

| Water Volume | Large (Thermal buffer) | Small (Fast response) |

| Startup Time | Slow (Heats large mass) | Fast (Low water mass) |

| Load Swing | Good for steady loads | Good for variable loads |

| Size/Footprint | Large and Heavy | Compact and Versatile |

| Maintenance | Easy access, forgiving | Sensitive to water quality |

To choose the best system, analyze your pressure and load needs. Regardless of the design, we supply the high-quality boiler tube you need for safe, efficient, and long-lasting industrial performance.