Vision/Value: Pragmatism, Integrity, Passion

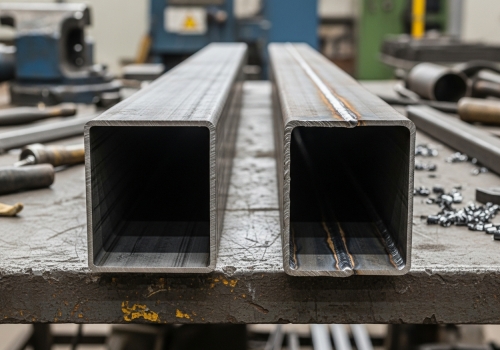

Finding the right structural steel for large projects is stressful for purchasing managers. If you choose materials with weak points or inconsistent quality, you risk project delays and safety failures. We provide high-strength seamless square tube solutions that ensure your engineering projects stand the test of time. A seamless square tube is a structural steel pipe with four corners and no welded seams. We manufacture it by cold-drawing or extruding a seamless round pipe into a square shape. This design gives it uniform strength around the entire cross-section, making it ideal for heavy load-bearing applications in construction and machinery.

Many suppliers offer square tubes, but few understand the critical difference between a standard pipe and a high-performance seamless one. I want to share my knowledge from years in the industry to help you make the best choice. Read on to understand the manufacturing, differences, and specific applications that matter for your projects.

You might worry about whether the steel grade meets your strict project standards. We solve this by strictly controlling raw materials and using advanced forming processes to guarantee quality. We make seamless square tubes by taking a mother seamless round pipe and passing it through a sizing and shaping mold. The material is usually high-quality carbon steel or low-alloy steel, such as Q235, Q345, or ASTM A500 grades. This process ensures exact dimensions and high structural integrity.

I have seen many clients confused about how we actually create these shapes. It is not just about bending a sheet of metal. The process is quite fascinating and requires precision. We start with a high-quality seamless round pipe. We do not use a flat steel strip. We unpack the round pipe and use heavy machinery to flatten, curl, and shape it. However, for true seamless tubes, we use cold drawing or extrusion. Cold drawing is very important for the final strength. We pull the round pipe through a square mold at room temperature. This changes the shape but keeps the metal grain structure tight. This increases the yield strength of the steel. The material choice is also vital for your project. In my experience at Centerway Steel, European and American clients usually ask for specific standards. We work with common carbon steel like Q235 and 20# steel. For projects needing more strength, we use low alloy steel like Q345 or ST52-3. Here is a simple table to help you match our materials with international standards:

| Material Category | Chinese Standard (GB) | American Standard (ASTM) | European Standard (EN) |

|---|---|---|---|

| Carbon Steel | Q235B, 20# | ASTM A500 Grade A/B | EN 10210 S235JRH |

| Low Alloy Steel | Q345B, 16Mn | ASTM A500 Grade C | EN 10210 S355J2H |

| High Strength | Q390, Q420 | ASTM A500 Grade D | EN 10219 S420MH |

We strictly follow these standards. This ensures that when you order a seamless square tube for a crane in Germany or a bridge in Southeast Asia, the chemical composition matches your engineering requirements perfectly.

Choosing between seamless and welded tubes can destroy your budget or your structural safety if you get it wrong. Seamless tubes offer superior pressure resistance, while welded tubes are more budget-friendly for lighter loads. The main difference is the manufacturing process and the presence of a seam. A seamless square tube comes from a solid round billet and has no weak points. A welded tube starts as a flat strip and has a welded line. Seamless tubes handle higher pressure and look better, but they cost more than welded options.

This is the question I get asked the most by purchasing managers like you. You want to save costs for your company, but you cannot compromise on safety. I understand this balance well. Let's break it down simply. A welded square tube is made from a steel strip. The factory rolls the strip and welds the edges together. You can sometimes see or feel this weld on the inside. In high-stress situations, the weld is always the weakest point. If the pressure gets too high, the tube will likely split at the seam. A seamless square tube does not have this problem. The metal is continuous. It acts as one solid unit. This makes it much safer for critical applications. For example, if you are building the arm of an excavator or a column for a skyscraper, you need seamless. The fatigue resistance is much better. This means it can handle shaking and vibration for years without cracking. However, price is a factor. Seamless production is slower and uses more expensive raw materials. Welded pipes are faster to make. If your project is just a simple fence or light furniture, a welded tube is fine. But for the heavy EPC projects we usually supply, seamless is the correct choice. Here is a comparison to help you decide:

| Feature | Seamless Square Tube | Welded Square Tube |

|---|---|---|

| Pressure Rating | Very High | Medium to Low |

| Weak Points | None (Uniform Strength) | The Weld Seam |

| Aesthetics | Smooth surface | Visible weld line (often) |

| Cost | Higher | Lower |

| Availability | Good for standard sizes | Good for all sizes |

| Main Use | Heavy machinery, Oil & Gas, Structural columns | Furniture, Light railing, Decor |

You need to know if a supplier can handle large diameters and specific wall thicknesses for your unique designs. We provide a massive range of sizes from 10mm up to 600mm to fit every part of your construction plan. Square and rectangular tubes follow strict size charts based on outer diameter and wall thickness. Common square sizes range from 10x10mm to 600x600mm. These tubes are essential in construction, transportation, and machinery because they resist bending and twisting better than other shapes.

When you look at the specs, you need to look at more than just the width and height. You must consider the performance characteristics. In the construction industry, we look at three main things: Plasticity, Hardness, and Impact Toughness. First, Plasticity. This is the ability of the seamless square tube to change shape under load without breaking. You want the steel to bend a little, not snap, if there is an earthquake or heavy wind. Second, Hardness. We measure this using Brinell (HB) or Rockwell (HRC) tests. A harder tube resists surface damage. This is vital if the tubes are exposed to rocks or heavy friction in mining equipment. Third, Impact Toughness. This is crucial for my clients in cold regions. When it is freezing, steel becomes brittle. Impact toughness measures how well the steel resists a sudden shock. A high-quality seamless tube will not shatter under impact load. We supply these tubes to four main industries:

1. Construction: We see these in the steel frames of airports and huge glass curtain walls. The hollow section is light but very stiff.

2. Machinery: Cranes and bulldozers use them for their arms. The seamless nature handles the hydraulic pressure well.

3. Transportation: Railway chassis and truck frames use them for safety.

4. Energy: Solar panel brackets and power tower structures. Since we focus on large diameter and heavy thickness products, we can meet special requirements. If you need a size that is not standard, we can often customize the mold. Here is a look at the typical size ranges we handle at Centerway Steel:

| Shape | Side Length Range (mm) | Wall Thickness (mm) |

|---|---|---|

| Square Tube | 10 x 10 ~ 600 x 600 | 1.0 ~ 30.0 |

| Rectangular Tube | 10 x 20 ~ 400 x 600 | 1.0 ~ 30.0 |

In summary, a seamless square tube offers unmatched strength, safety, and reliability for your heavy construction projects compared to welded alternatives. At Centerway Steel, we combine top-tier manufacturing with strict quality control to ensure you get the exact specs you need.