Sharing China-Made with Global Customers

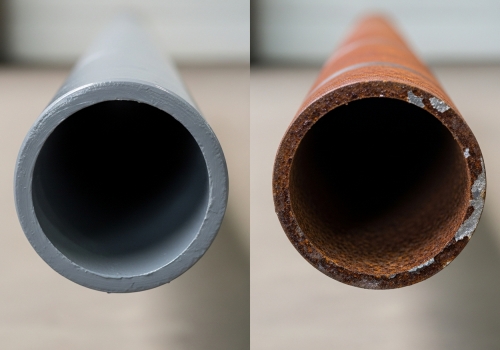

Corrosion eats through pipeline budgets faster than you think. If you worry about leaks, high maintenance costs, and project delays, you must understand how to protect your steel investments properly. An epoxy coated pipe is a steel pipe protected by a layer of Fusion Bonded Epoxy (FBE). This coating provides a hard, smooth surface that resists chemicals, moisture, and soil stress. It effectively extends the lifespan of pipelines in oil, gas, and water systems by preventing rust and corrosion.

Many project managers rush the material selection process. They look at the base price of the steel but forget the cost of failure. I have seen this happen too many times in my years in the industry. But you are different. You are here to learn the truth about these coatings. So, let us look closer at the details.

You might wonder if a thin layer of powder can really stop rust. The secret lies not just in the material, but in the precise application method we use. The process involves cleaning the steel pipe to a near-white metal finish. We heat the pipe to a specific temperature and spray electrostatic epoxy powder onto it. The powder melts and cures instantly, bonding directly to the steel surface to form a continuous, solid barrier against the elements.

I have spent decades in this industry, and I know that the application process is just as important as the material itself. When we manufacture an epoxy coated pipe, we follow a strict set of steps. First, we blast the steel surface. This removes all dirt, grease, and mill scale. It gives the steel a rough texture. This texture helps the epoxy grab onto the metal. Next, we heat the pipe using induction heating. The temperature must be perfect. If it is too hot, the epoxy burns. If it is too cold, it does not cure. We usually aim for around 230°C to 250°C. Once the pipe is hot, we pass it through a spray booth. Here, charged epoxy powder lands on the pipe. It melts and turns into a liquid film. Then, it cools down and hardens. This is what we call Fusion Bonded Epoxy (FBE). Sometimes, clients need more protection. In these cases, we use a 3-layer system (3PE). This includes the epoxy layer, an adhesive layer, and a polyethylene outer layer. This combination offers the best mechanical protection. Below is a breakdown of the coating structures we often supply:

| Coating Type | Layer 1 | Layer 2 | Layer 3 | Main Benefit |

|---|---|---|---|---|

| FBE (Single Layer) | Fusion Bonded Epoxy | N/A | N/A | Excellent steel adhesion and chemical resistance. |

| 2LPE | Adhesive | Polyethylene | N/A | Good waterproofing, lower cost. |

| 3LPE | Fusion Bonded Epoxy | Copolymer Adhesive | Polyethylene | High mechanical strength and corrosion resistance. |

Every product has strong points and weak points. You need an honest assessment to decide if this coating fits your specific engineering requirements and budget limits. The main advantage is superior corrosion resistance and improved flow efficiency due to surface smoothness. However, FBE coatings can be brittle and suffer damage during rough transport. They are also sensitive to UV light, meaning they should not be stored outdoors for long periods without cover.

Let's talk about value. As a purchasing manager, you want a product that lasts. An epoxy coated pipe can last 30 to 50 years underground. The coating creates a barrier that oxygen and water cannot cross. This stops rust before it starts. Also, the inside surface of the coating is very smooth. This is great for fluid transport. Friction is lower, so you save energy on pumping. Another big plus is chemical resistance. If your pipeline carries oil, gas, or industrial waste, chemicals can eat bare steel. Epoxy resists most acids and alkalis. This makes it a safe choice for harsh environments. It is also safe for drinking water if you choose the right grade of powder. But, I must be honest with you. There are downsides. The biggest issue is impact damage. FBE is hard, which means it can crack if you hit it with a rock or drop it hard during loading. We have to be very careful during shipping. We use special caps and spacers to protect the pipes. Also, standard FBE hates the sun. UV rays turn the coating chalky over time. If your pipes sit in a yard for months, they need tarps. If you need pipes for above-ground use, we might suggest a UV-resistant topcoat instead.

Buying steel from overseas can feel risky without the right paperwork. Standards are the language we use to guarantee that the product matches your design specs perfectly. International standards like DIN 30670, CAN/CSA Z245.20, and ASTM A775 dictate the thickness, hardness, and testing methods for coatings. These certifications ensure the epoxy coated pipe meets strict criteria for cathodic disbondment and impact resistance, protecting your company from liability.

In Germany and across Europe, quality is everything. I know you cannot accept a product that fails inspection. That is why we at Centerway Steel stick to global standards. When you order an epoxy coated pipe, you should look for specific certifications. For European projects, DIN 30670 is very common for polyethylene coatings on steel pipes. For FBE specifically, we often look at NACE standards or CSA Z245.20. These standards tell us how to test the pipe. For example, we do a "Holiday Test." This has nothing to do with a vacation. We run a high-voltage ring over the pipe. If there is even a tiny pinhole in the coating, the machine sparks and beeps. We reject that pipe or repair it immediately. We also test for "Cathodic Disbondment." This tests how well the coating stays stuck to the steel when there is an electrical current in the soil. If the coating peels off, corrosion spreads. A good epoxy pipe resists this peeling. We also check the thickness. Standard FBE might be 300 to 400 microns thick. We measure this constantly during production. When you work with a supplier, always ask for the MTC (Mill Test Certificate). It proves we did these tests.

Epoxy coated pipes offer a robust defense against corrosion for industrial pipelines. By understanding the manufacturing process, pros, cons, and quality standards, you secure a long-lasting, cost-effective piping system.