Sharing China-Made with Global Customers

Are you struggling to decide between ASTM A53 and A106 pipes for your project? Choosing the wrong grade causes project delays, safety risks, and unnecessary expenses. Here is the clear comparison you need. The main difference in a53 vs a106 lies in their application and manufacturing. A106 is exclusively seamless and designed for high-temperature service. A53 can be welded or seamless and is typically used for low-to-medium pressure transport of air, steam, water, and for structural purposes.

Understanding these specifications is vital for your next order. Let me explain the details so you can buy with confidence and avoid mistakes.

You cannot afford structural weakness in your pipeline. Knowing how the pipe is made prevents catastrophic failures in your engineering projects and ensures safety. A106 is strictly manufactured as a seamless pipe to withstand stress. A53 comes in three types: Type F (furnace-butt welded), Type E (electric-resistance welded), and Type S (seamless), offering more versatility for less critical applications.

As a supplier serving the global market since 1996, I see many purchase orders. The most common confusion happens here. You need to look at the "Type." ASTM A106 is always seamless. We make it by piercing a solid steel bar (billet) while it is hot. There is no welding seam. This means the strength is the same all around the pipe. It is perfect for high pressure. ASTM A53 is different. It gives you options.

| Feature | ASTM A106 | ASTM A53 |

|---|---|---|

| Manufacturing Method | Seamless Only (Hot Finished or Cold Drawn) | Seamless (Type S) or Welded (Type E, Type F) |

| Primary State | Killed Steel | Open Hearth, Basic Oxygen, or Electric Furnace |

| Surface Finish | Usually rougher due to heat treatment | Can be bare, oiled, or galvanized |

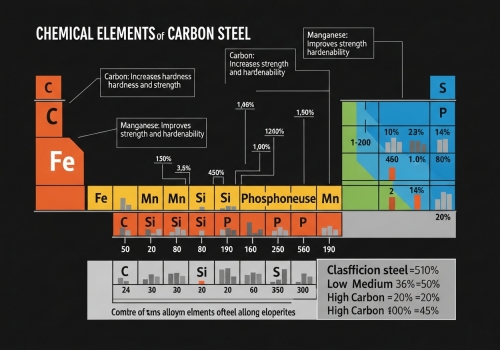

High temperatures destroy standard steel pipes quickly. Ignoring chemical elements like silicon leads to unexpected replacement costs and dangerous downtime in your plant. The critical factor in the a53 vs a106 chemical battle is silicon. A106 contains silicon to boost heat resistance for high-temperature service. A53 lacks this requirement, making it unsuitable for extreme heat environments.

This is the invisible difference. You cannot see silicon with your eyes, but your equipment knows it is there. ASTM A106 steel must contain a minimum amount of silicon. Usually, this is around 0.10% minimum. Why is this important? Silicon helps the steel resist oxidation at high temperatures. If you run a power plant or a refinery, the pipes get very hot. Without silicon, the pipe degrades fast. ASTM A53 does not require minimum silicon. It is made for standard temperatures. It contains carbon, manganese, phosphorus, and sulfur. These elements determine the strength (Yield and Tensile). Both A53 and A106 have similar strength grades, like Grade B. This confuses buyers. They see "Grade B" and think the pipes are the same. They are not. We test these chemical limits in our labs. We provide you with a Mill Test Certificate (MTC). This paper proves the chemistry. If you work on a project in the Middle East or Europe, you need this proof. We also ensure that impurities like Sulfur (S) and Phosphorus (P) are low. This makes the steel better quality. But we add enough to make sure you can cut and thread the pipe easily (machinability).

| Chemical Element | A106 Grade B (Max %) | A53 Grade B (Max %) |

|---|---|---|

| Carbon (C) | 0.30% | 0.30% |

| Manganese (Mn) | 0.29% - 1.06% | 1.20% |

| Phosphorus (P) | 0.035% | 0.050% |

| Sulfur (S) | 0.035% | 0.045% |

| Silicon (Si) | 0.10% Min | Not Specified |

Over-specifying materials hurts your project budget significantly. Buying expensive seamless pipe for simple structural needs is a waste of company resources. Use A106 for high-pressure, high-temperature applications like oil refineries, power plants, and gas boilers. Choose A53 for standard low-pressure conveyance of water, air, or steam, and for structural support.

I have worked with many purchasing managers in Germany and worldwide. The goal is always the same: Quality and Cost Control. Here is how you apply the a53 vs a106 rule to save money. When to choose A106: Use this for the "hard" jobs. Think about boiler tubes, steam lines, and oil refineries. If the fluid inside is very hot or under high pressure, A106 is the safe choice. It costs more, but it handles the stress. It resists vibrations and heat cycles. When to choose A53: Use this for the "utility" jobs. If you are moving water across a site, use A53. If you are building a support rack or a low-pressure air line, use A53. Also, A53 is often galvanized (zinc coated). A106 is rarely galvanized. If you need corrosion protection for an outdoor water line, A53 is the winner. The Dual Certified Solution: Sometimes, we supply "Dual Certified" pipe. This pipe meets the standards for both A106 Grade B and A53 Grade B Type S. This is very helpful for inventory. You can stock one type of pipe and use it for both applications. It simplifies your warehouse. At Centerway Steel, we often suggest this to our EPC clients. It reduces the risk of using the wrong pipe. We pack and mark these pipes clearly so your site team knows exactly what they have.

| Application Scenario | Recommended Standard | Reason |

|---|---|---|

| High Temp Steam Lines | ASTM A106 | Silicon content resists heat degradation. |

| Structural Columns | ASTM A53 | Cost-effective, high strength not required. |

| Potable Water Transport | ASTM A53 (Galvanized) | Zinc coating prevents rust; low pressure. |

| Oil & Gas Refining | ASTM A106 | Seamless nature withstands high pressure. |

A106 is for high heat and pressure; A53 is for general use. Choosing correctly ensures safety and saves budget. Contact Centerway Steel for professional advice today.