Sharing China-Made with Global Customers

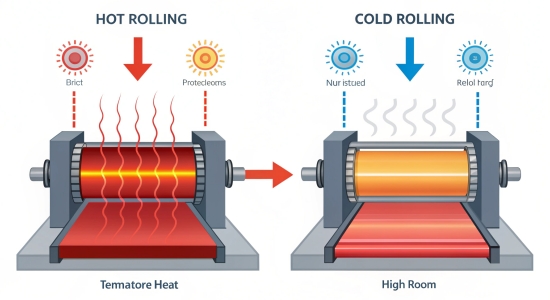

Sourcing the wrong steel material can ruin your project budget and delay your construction timelines. If you do not understand the fundamental differences in manufacturing, you might pay too much for unnecessary quality or buy material that fails during assembly. Hot vs cold rolled steel refers to the temperature at which the metal is processed. Hot rolling happens above recrystallization temperatures for easier shaping and lower cost, while cold rolling happens at room temperature to increase strength and precision. Knowing this difference ensures you buy the right material for your specific engineering needs.

Many buyers believe that steel is just steel, but this simple mistake can cost an EPC company thousands of dollars. Let me explain exactly how these two processes change the DNA of the metal so you can make the smart choice.

Dealing with tight budgets on large structural projects is stressful for any purchasing manager. Using overpriced, high-precision steel where it is not actually needed kills your profit margin and adds no real value. Hot rolled steel is pressed at temperatures over 1,700°F. This extreme heat makes the steel easy to form and much cheaper to produce. It is the best choice for large structural components like I-beams and railroad tracks where precise shapes and smooth finishes are not the main priority. When we talk about hot rolled steel at Centerway Steel, we are talking about a process that starts with a large metal slab called a billet. We heat this billet until it glows white-hot. At this temperature, the steel is soft. We can roll it flat or shape it easily. Because we process it above the "recrystallization temperature," the steel does not get hard while we work it. This makes it very easy for us to shape into massive sizes for big construction jobs. However, you must know the downsides. When steel cools down, it shrinks. Because hot rolled steel cools at the end of the process, we cannot control the final size perfectly. You will often see these characteristics:

· Scaly Surface: The cooling process leaves a rough, blue-grey finish.

· Rounded Edges: The material is not sharp; the corners are soft.

· Loose Tolerances: The size might vary slightly because of the shrinking. For my clients in the oil and gas industry or general construction, I always recommend hot rolled steel for things that you will not see. If you are building the frame of a warehouse or burying pipes underground, you do not need a shiny surface. You need strength and low cost. This material is free from internal stresses because it cools slowly, meaning it won't warp when you cut it. It is the workhorse of the industry.

Rough surfaces and loose tolerances can cause major assembly failures in precision engineering. Nothing is worse than rejecting a batch of pipes or parts because they do not fit together perfectly on the site. Cold rolled steel is actually hot rolled steel that undergoes further processing. We cool it and re-roll it at room temperature to achieve tighter tolerances and smoother surfaces. While this increases the price, the hot vs cold rolled steel comparison shows cold rolling is essential for precision parts.

To understand cold rolled steel, you have to think of it as "refined" steel. We take the hot rolled steel, let it cool down, and then put it through the rollers again. But this time, we do not add heat. Because the steel is cold, it is much harder to shape. We have to use high-pressure rollers to squeeze it. This process is called "work hardening." This extra work does amazing things to the metal. It can make the steel up to 20% stronger than it was before. But the main reason my customers ask for this is not just strength; it is about the finish and the fit.

· Surface: It comes out smooth, shiny, and oily. It looks good.

· Precision: Because it does not shrink (it is already cold), the size we roll is the size you get. It is exact.

· Edges: The corners are sharp and well-defined. However, this comes at a price. It takes more energy and time to roll cold metal. Also, the process creates "internal stress." Imagine bending a paperclip back and forth; it gets hard. Cold rolled steel has tension inside it. If you cut it the wrong way, it might warp. We often have to anneal it (heat it up slightly) to relieve this stress. I usually suggest this for visible parts like metal furniture, car bodies, or precision tubing where the diameter must be exact.

Making the wrong choice leads to structural weakness or wasted budget on your final balance sheet. You cannot afford to guess when safety standards and project money are at risk. To decide, look at your project's function. If the steel is hidden and structural, choose hot rolled to save money. If the steel shows or needs exact dimensions, choose cold rolled. Understanding the hot vs cold rolled steel trade-offs helps you balance quality with your budget.

When I sit down with engineers and purchasing managers, I often see them looking at the "Grade" of the steel (like 304 stainless or A36 carbon) but forgetting about the processing method. These are two different things. You can have the same grade of steel processed in two different ways. The decision usually comes down to three factors: Budget, Visibility, and Precision. I have created this table to help you visualize the trade-offs we face in the steel industry:

| Feature | Hot Rolled Steel | Cold Rolled Steel |

|---|---|---|

| Primary Benefit | Lower Price & Workability | Surface Finish & Precision |

| Process Temp | Above 1700°F (Hot) | Room Temperature (Cold) |

| Surface Finish | Rough, Scaly, Blue-Grey | Smooth, Shiny, Greasy |

| Dimensional Tolerance | Loose (Due to shrinking) | Strict (Very precise) |

| Material Strength | Standard (Normalized) | Higher (Work Hardened) |

| Internal Stress | Low (Stable) | High (Can warp if cut) |

| Best Use Case | I-Beams, Railroads, Construction | Appliances, Precision Tubing |

However, if you are making parts for a machine where smooth movement is key, or if you need a specific aesthetic for an architectural project, you must pay the extra money for cold rolled. The extra strength is a bonus, but the real value is that you do not have to do extra work to make it look good or fit right. At Centerway Steel, we help you analyze your drawings to see where you can save money with hot rolled and where you must invest in cold rolled.

Hot rolled steel is best for structural, cost-sensitive projects, while cold rolled steel offers superior strength and precision for detailed work. Contact Centerway Steel for the right advice.