Sharing China-Made with Global Customers

Have you ever repaired a leak, restarted the unit, and then faced another shutdown immediately? It costs you time and money. You need to stop fixing symptoms and start finding the real problem. Boiler tube failure analysis is the critical process of identifying the specific root cause of a tube rupture, whether it is from corrosion, stress, or fatigue. By performing a thorough assessment of both the tube and the operational history, you can implement the right solutions to prevent recurring outages.

Many operators make the mistake of just patching the hole and moving on. This approach ignores the underlying issues that will eventually destroy your entire system. Let's look at the specific failures so you can stop them.

Water looks harmless, but inside a boiler, it can be a destructive force. If you ignore water chemistry, your pipes will erode from the inside out, leading to dangerous leaks. Waterside failures typically stem from poor chemical control, resulting in caustic attacks, oxygen pitting, or hydrogen damage. These mechanisms attack the internal diameter of the tube, often requiring a strict review of your water treatment protocols and a potential upgrade in tube material quality.

I have been in the steel pipe industry since 1996, and I often see customers puzzled by leaks in relatively new pipes. Often, the steel quality is fine, but the boiler tube failure analysis points to water chemistry. When we look at the "waterside" of the tube, we are looking at how the water interacts with the steel. The three biggest enemies here are caustic chemicals, oxygen, and acid. For example, Caustic Attack happens when deposits block water flow. This creates a hot spot where chemicals concentrate and eat away the protective layer of the steel. You will usually see a gouge on the inside surface. Then there is Oxygen Pitting. This looks like someone took a drill to the inside of your tube. It happens when air gets into the system, usually during downtime. To help you understand this better, I have broken down the main waterside threats below. You need to know these to talk effectively with your maintenance team.

| Failure Mechanism | What it looks like (Symptoms) | The Root Cause | The Solution |

|---|---|---|---|

| Caustic Attack | Wall loss and gouging on the Inside Diameter (ID). | Heavy deposits causing chemicals to concentrate. | Clean the tubes to remove deposits and balance the water pH. |

| Oxygen Pitting | Deep, irregular holes or pits on the ID. | Too much oxygen in the water, often during startup or storage. | Improve deaeration and use proper storage procedures during outages. |

| Hydrogen Damage | Micro-cracks inside the metal; the tube becomes brittle. | Corrosion releases hydrogen, which enters the steel and weakens it. | Prevent scale buildup and strictly control acidic contaminants. |

| Stress Corrosion | Thick, brittle cracks near welds or attachments. | High stress combined with corrosive fluids. | Avoid water carryover and ensure proper cleaning procedures. |

The outside of your boiler tubes faces a brutal environment of fire, ash, and shifting temperatures. If you do not select the right materials, the tubes will wear down rapidly. Fireside failures occur on the external surface of the tube and include fuel ash corrosion, erosion, and thermal fatigue. These issues are caused by abrasive fly ash, melting slag, and constant heating and cooling cycles, which strip away metal and cause surface cracking.

While waterside issues are hidden, fireside issues are often more visible but just as deadly. In my experience supplying pipes to EPC companies, I know that the type of fuel you burn matters a lot. Coal, oil, and gas all affect the steel differently. Boiler tube failure analysis on the fireside often reveals that the material was not strong enough for the environment. For instance, Fuel Ash Corrosion is a major issue for coal-fired boilers. The ash melts onto the tube and creates a liquid layer that eats the metal. It makes the tube look "pock-marked." If you are seeing this, you might need tubes with higher Chromium content (more than 20%). Another common issue I see is Erosion. This is purely mechanical. It is like sandblasting your pipes. Fly ash or steam from sootblowers hits the tube at high speed and wears it down. This makes the wall thinner until it bursts. Here is a breakdown of what happens on the outside of the tube:

| Failure Mechanism | What it looks like (Symptoms) | The Root Cause | The Solution |

|---|---|---|---|

| Fuel Ash Corrosion | External wall loss; pock-marked surface under the scale. | Molten ash elements attack the hot metal surface. | Use high-chromium steel tubes or install stainless steel shields. |

| Fireside Fatigue | "Elephant hide" or "alligator skin" cracking on the surface. | Constant heating and cooling (cycling) cracks the scale. | Reduce rapid startups/shutdowns and optimize sootblowing. |

| Erosion | Metal loss on the impact side; the tube looks polished or worn. | Abrasive ash or steam hitting the tube at high speed. | Install tube shields and balance the gas flow in the boiler. |

| Waterwall Corrosion | Thinning of the tube wall in the furnace area. | A "reducing atmosphere" caused by poor combustion. | Use weld overlays (coating the tube) with high-Nickel materials. |

Sometimes a tube fails not because of corrosion, but because it was pushed beyond its physical limits. These mechanical failures are often sudden, violent, and very dangerous for your personnel. General mechanical failures, such as short-term overheating and dissimilar metal weld failures, happen when the tube metal temperature exceeds its design limits or when physical stresses tear the joints apart. Identifying the difference between a sudden "fish mouth" burst and long-term creep is essential for safety.

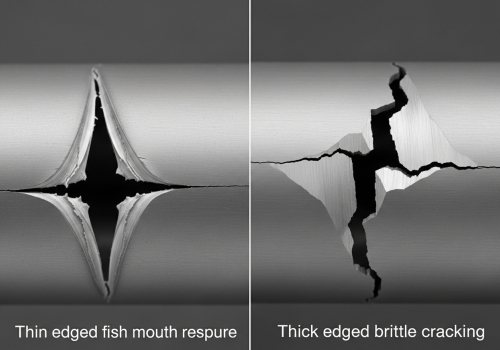

This is the final piece of the puzzle. When I talk to engineers, they often confuse different types of overheating. However, in boiler tube failure analysis, the shape of the hole tells you the whole story. There are two main types of overheating. First, there is Short-term Overheat. This happens fast. Imagine a blockage stops water flow during startup. The steel gets incredibly hot (over 870°C) and blows out like a balloon. We call this a "fish mouth" failure because it looks like wide lips with thin edges. Second, there is Long-term Overheat, also known as Creep. This is a slow death. Over years, the tube swells slightly and develops thick, rough cracks. It means the tube has reached the end of its life. We also cannot ignore weld failures. Many systems join stainless steel to carbon steel. These are called Dissimilar Metal Welds (DMW). Because these metals expand at different rates when hot, they can rip apart at the weld line.

| Failure Mechanism | What it looks like (Symptoms) | The Root Cause | The Solution |

|---|---|---|---|

| Short-term Overheat | "Fish mouth" rupture with thin, razor-like edges. | Lack of cooling flow causing sudden temperature spikes. | Check for blockages and follow proper startup procedures. |

| Long-term Overheat | Minimal swelling with a narrow, longitudinal split. | Operating at slightly high temperatures for years (Creep). | Replace aged tubes and clean scale that blocks heat transfer. |

| DMW Failure | A complete break along the weld line between two metals. | Stress from different expansion rates of the metals. | Replace with Nickel-based filler welds or better joint designs. |

| Graphitization | Brittle failure with no warning. | Carbon steel degrades after long exposure to moderate heat. | Replace carbon steel with alloy steel (like Chrome-Moly) in hot zones. |

As a supplier, I always advise clients: if you see creep damage, do not patch it. Replace the section. It is a sign that the metal structure is gone.

To prevent shutdowns, you must perform a proper boiler tube failure analysis to distinguish between waterside corrosion, fireside erosion, and mechanical overheating. At Centerway Steel, we supply the high-quality alloy and carbon steel pipes you need to solve these problems permanently.