Sharing China-Made with Global Customers

The “round to square” conversion of a seamless steel tube is a specialized metal forming process that changes the cross-section of a round tube into a square or rectangular one. This transformation is achieved through cold working, which causes plastic deformation at room temperature without altering the tube’s internal integrity.

The process follows the principle of constant neutral line circumference, meaning the length of the tube’s neutral layer remains nearly unchanged while its cross-sectional shape transforms. By converting a circular cross-section into a square or rectangular shape, the product gains higher section modulus and improved bending resistance — all while saving material and enhancing overall strength.

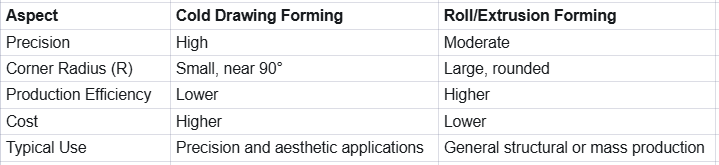

The “round to square” conversion of a seamless steel tube can be achieved through two main methods: cold drawing and roll forming (extrusion forming).

This method involves pulling a seamless round tube through a high-hardness mold whose shape matches the desired square cross-section. The process includes several stages such as cutting, pickling, heading, cold drawing, trimming, and straightening.

Advantages:

· High dimensional precision and near-right-angle corners.

· Excellent surface quality when properly controlled.

Disadvantages:

· Higher processing cost and lower production efficiency.

· Possible surface defects such as scratches or folds if not carefully managed.

In this method, the seamless round tube passes through a series of specially designed rolling dies, gradually transforming into a square shape under continuous pressure.

Advantages:

· High production efficiency and minimal material waste.

· Lower manufacturing cost.

Disadvantages:

· Larger corner radius (R) and less sharp edges compared to cold drawing.

Depending on the drive type, roll forming can be categorized into active and passive systems, offering flexibility in large-scale industrial production.

A typical cold drawing process for seamless steel tube square conversion includes:

1. Material Preparation: Selecting high-quality seamless round tubes as the base material.

2. Pretreatment: Cutting, pickling, and cleaning to remove surface oxides.

3. Forming: The core stage where the round tube is reshaped through cold drawing or rolling.

4. Finishing and Heat Treatment: Including end trimming, straightening, and optional annealing to relieve internal stress.

5. Inspection and Packaging: Dimensional checks and surface quality inspection before storage or shipment.

Key Technologies:

· Precision Mold Design: Determines final shape accuracy and production efficiency.

· Process Parameter Control: Proper deformation ratio and drawing speed are critical for consistent quality.

· Lubrication and Cooling: Reduce friction and heat to prevent surface damage and extend die life.

· Simulation and Optimization: Modern software simulation helps optimize process parameters and predict deformation results.

Compared with welded square tubes, seamless steel tube products produced through the “round to square” process have no welding seams, ensuring better uniformity, higher mechanical strength, and superior fatigue and pressure resistance.

The square and rectangular tubes produced from seamless steel tube transformation are widely used due to their lightweight structure, excellent strength, and smooth surface quality. Common application areas include:

· Construction & Structural Engineering: Roof trusses, columns, frames, and beams in modern steel structures and high-rise buildings.

· Machinery & Industrial Equipment: Machine frames, conveyor supports, and load-bearing components in heavy machinery.

· Transportation: Automotive frames, aircraft structures, shipbuilding, and metro car bodies.

· Furniture & Decoration: High-end furniture, architectural decoration, railings, and stair structures.

· Other Fields: Power plants, agricultural machinery, curtain walls, bridges, pressure vessels, and medical equipment.

The “round to square” processing technology greatly expands the usability and versatility of the seamless steel tube.

· For high precision and aesthetic needs, cold drawing is the preferred method.

· For high output and cost efficiency, roll forming provides excellent performance.

In summary, by mastering the “round to square” forming techniques, manufacturers can produce square and rectangular seamless tubes with outstanding strength, precision, and adaptability — meeting the demands of industries from construction to advanced engineering.