Sharing China-Made with Global Customers

3PE coated steel pipe (three-layer polyethylene coated steel pipe) is currently the most advanced anti-corrosion technology widely used in oil, gas, and water transmission pipelines. This multilayer coating system provides superior protection against corrosion, mechanical damage, and environmental factors, significantly extending the service life of steel pipes in harsh conditions.

The 3PE coating process involves three distinct layers that work synergistically to provide comprehensive protection:

· Thickness: ≥100μm

· Function: Provides excellent adhesion to the steel surface and acts as a primary corrosion barrier

· Characteristics:

o Chemically bonds to the steel surface

o Excellent cathodic disbondment resistance

o High temperature resistance (up to 100°C)

· Thickness: 170-250μm

· Function: Creates a strong bond between the FBE and outer PE layers

· Material: Typically ethylene acrylic acid (EAA) or maleic anhydride grafted polyethylene

· Thickness: 2.5-3.7mm

· Types:

o High-density polyethylene (HDPE) for most applications

o Medium-density polyethylene (MDPE) for improved flexibility

· Functions:

o Mechanical protection against impact and abrasion

o Moisture barrier

o UV resistance for above-ground applications

· Withstands pH range from 3 to 11

· Resistant to soil stress and microbiologically influenced corrosion (MIC)

· Excellent performance in both marine and industrial environments

· Impact resistance: ≥10J/mm (tested at -30°C)

· Hardness: ≥55 Shore D

· Penetration resistance: ≥3mm (at 80°C)

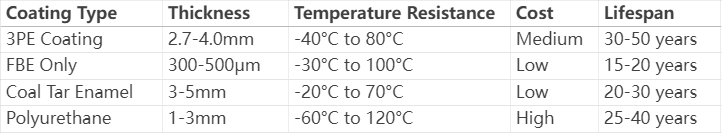

· Service life: 30-50 years depending on environment

· Temperature range: -40°C to +80°C

· Minimal maintenance requirements

1. Surface Preparation

o Sandblasting to Sa 2.5 cleanliness

o Anchor profile of 50-100μm

2. FBE Application

o Electrostatic powder spraying at 200-250°C

3. Adhesive Application

o Extrusion coating while FBE is still reactive

4. PE Extrusion

o Side extrusion or circumferential wrapping

o Cooling and inspection

3PE coated steel pipes must comply with:

· ISO 21809-1:2011 (Petroleum and natural gas industries)

· DIN 30670 (Polyethylene coatings for steel pipes)

· CAN/CSA-Z245.21 (External polyethylene coating)

· Oil and gas transmission pipelines

· Water supply networks

· Chemical processing pipelines

· Underground cable protection

· Piling and structural applications

While 3PE coated steel pipe requires minimal maintenance, regular inspections should include:

· Holiday detection (DC voltage test)

· Coating adhesion tests

· Cathodic protection monitoring

The 3PE coated steel pipe represents the gold standard in pipeline corrosion protection, combining the chemical resistance of epoxy, the bonding strength of adhesive, and the mechanical protection of polyethylene. This multi-layer system offers unmatched performance for critical infrastructure projects where long-term reliability is essential.

For pipeline projects requiring maximum protection with minimal maintenance, 3PE coated steel pipe remains the preferred choice among engineers and project managers worldwide.